Porsche Cayenne Common Problems

Common Reliability or Mechanical Issues Diagnosed on the Porsche Cayenne

All You Need to Know About Porsche Cayenne Common Problems, Reliability, and Mechanical Issues

All You Need to Know About Porsche Cayenne Common Problems, Reliability, and Mechanical Issues

Listed below are Porsche Cayenne common mechanical problems with their likely resolutions. These are the most frequent Cayenne problems and mechanical issues for the 955, 957, 958, and 9YO that were diagnosed by repair shops.

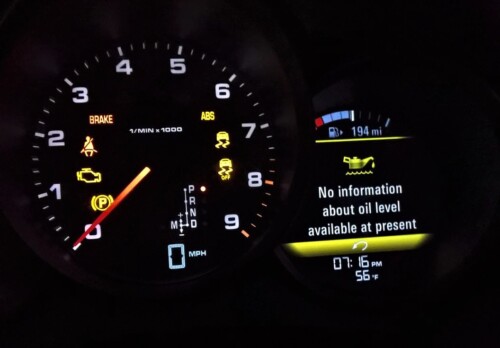

What to do if You See Warning Lights, Messages, or Symbols on Your Porsche Cayenne Dashboard

What to do if You See Warning Lights, Messages, or Symbols on Your Porsche Cayenne Dashboard

Often a Porsche Cayenne common problem or mechanical issue will be associated with a dashboard warning light, message, or symbol. Be aware, there are more problems than there are warning lights or symbols and often the lights and messages are not always that clear. In our Dashboard Warning Lights, Messages, and Symbols section, we recommended what action to take when you see a warning on your Porsche dashboard.

Maintenance Won’t Solve Porsche Cayenne Problems

Maintenance rarely solves a problem. However, neglecting maintenance can cause issues – check your last service update with our recommended Cayenne maintenance schedules.

Understanding Cayenne Diagnostic Trouble Codes

Understanding Cayenne Diagnostic Trouble Codes

Check engine light? Have you scanned your Cayenne and are now not sure what to make of those OBD codes? Our article on how to interpret and make sense of those fault codes may help. The following sections identify common problems through symptoms. If you have scanned your Porsche OBD2 system and have identified fault codes, go to our Porsche powertrain fault code page to get additional fault code descriptions.

Can’t Find An Answer Below? – Contact Us For Help

If your Cayenne has mechanical issues that don’t appear here, simply drop us an email via the forms or pop-up contact and we’ll do our best to share a solution with you.

Porsche Cayenne Reliability

The fact the car is a fine tuned Porsche can often lead to what would normally be deemed expensive repairs when compared to a domestic pickup truck or SUV. You’re driving a Porsche, so the reliability and repair cost comparison is invalid in our opinion! In general, the Cayenne has no scary common issues that should ever stop you owning and enjoying one.

Clicking on a heading below gives you more detail.

Porsche Cayenne Common Problems by Symptom – 955 | 957 | 958 | 9Y0

Engine

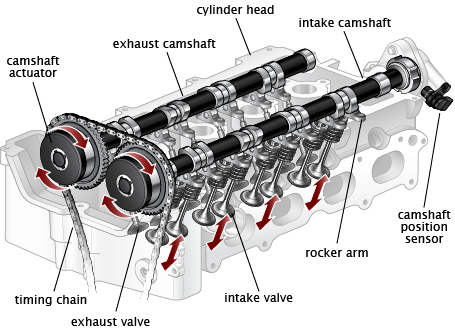

Check Engine Light - Power Loss - Incorrect Valve Lift - 957 - 958

Symptoms: Loss of Power, Check Engine Light, Incorrect Valve Lift Fault

Symptoms: Loss of Power, Check Engine Light, Incorrect Valve Lift Fault

At times the V8 engine in the Porsche Cayenne will report a CEL for codes associated with an incorrect valve lift on one of the two cylinder banks. There are two reasons for this – one obvious and one less so.

Valve Lift Solenoid Failure

First, a electromechanical solenoid that controls oil flow to the cams can fail. This causes the regulation of the valve lift to be reported as inconsistent or not correct. On most occasions replacing the solenoid will solve the problem. However, if the solenoid replacement doesn’t solve the problem, you could be left scratching your head as to why the report of incorrect valve lift returns.

O2 Sensor Problem

The answer lies in a not so obvious location. Valve lift is determined by the front O2 sensor. Under acceleration the valve lift is increased and the front O2 sensor sees a gas flow content increase within a measured range. A failing front O2 sensor will either not see or cannot react in time to the valve lift gas flow change. The slow response from the O2 sensor is not within the tolerance the engine management system requires and therefore a valve lift fault is set as a result. Replacing the front O2 sensor will typically solve this problem.

Check Engine Light - Misfire - Dead Cylinder - Coils, Plugs, Lifters

Symptoms: CEL, Loss of Power, Misfire Under Load

There are multiple reasons why a check engine light can be set for misfires. A code scan can reveal which cylinder is misfiring but not usually exactly the reason why am misfire is happening.

CEL – Misfire – Faulty Ignition Coil

CEL – Misfire – Faulty Ignition Coil

The ignition coils on the Porsche Cayenne V8 have been updated a number of times. A single coil failure is typically a sign of more trouble to come from other coils. It’s usually best practice to update all the ignition coils if the problem is caused by age or mileage.

A failing coil typically stops any spark and sets a misfire code with a completely dead cylinder. This will cause rough running, especially at idle.

However, coils can also part fail, where a weak spark causes misfires to occur when the cylinder is loaded under acceleration. Resetting the cylinder and clearing the CEL fault will cause the engine to run well at idle but set the fault again when driven more aggressively.

CEL – Misfire – Worn Spark Plugs

CEL – Misfire – Worn Spark Plugs

Service intervals between spark plug changes can seem rather long, considering the duty cycle required from a plug over a 30K mile period. Worn spark plugs typically initially produce a loss of power, a change in fuel consumption, and then set faults for misfires. With worn spark plugs, you may see misfires on one cylinder or random multiple misfires across the engine.

A shortcut to finding out if you have a plug or coil problem is to identify the cylinder that is misfiring and swap the coil from the misfiring cylinder with a coil from a known good cylinder. If the misfire moves with the coil, you have a coil problem. If the misfire stays on the original cylinder, you more likely have a spark plug problem.

CEL – Misfire – Dead Cylinder

CEL – Misfire – Dead Cylinder

Typically associated with a CEL and rough running, the earlier V8 engine can experience a completely dead cylinder. Of course, replacing the plug and coil is the first step but, if the problem persists we’d recommend compression testing the cylinder involved.

Commonly, the issue is an intake lifter that is stuck or broken. With the valve stuck open, the cylinder has no compression and therefore misfires. If you’re lucky, this can be solved by replacing just the stuck or broken lifter.

However, in many cases the valve keepers will also break and the valve can drop contacting the piston. This requires significantly more extensive work and the removal of the head.

Fault Oil Pressure Monitoring Warning Message

Symptoms: Warning Message – Oil Pressure Monitoring Drive on Permitted. Visit Workshop.

Symptoms: Warning Message – Oil Pressure Monitoring Drive on Permitted. Visit Workshop.

Cayenne owners can experience this message when driving. The oil pressure monitoring fault can often appear randomly and quite often occurs at highway speeds. Around town, the message is less likely to appear.

Oil pressure warnings can be scary. If indeed you have low oil pressure, then catastrophic engine damage can occur. So, it’s best not to ignore this and to quickly investigate the cause. The question here is related to whether the message is genuine e.g. a mechanical pressure fault or an electrical anomaly.

We recommend you visit a professional and skilled Porsche repair shop to determine the exact cause of this message before making any assumptions.

We are aware of owners who have had to replace oil pumps and oil pressure relief valves, however, the likely cause of this issue is related to an electrical failure of the oil pressure sensor.

We are aware of owners who have had to replace oil pumps and oil pressure relief valves, however, the likely cause of this issue is related to an electrical failure of the oil pressure sensor.

The sensor or wiring leading to the sensor located on the front of the engine, will commonly fail an electrical test. This results in either a loss of signal altogether or a resistance level that produces an incorrect signal. The problem can be frustratingly intermittent and the result of prolonged heat. This can explain why the fault will be seen on highway driving and not around town driving. The issue does not normally set faults but merely records an events.

So, when you get to the shop without the message the problem is not there! Low level diagnostic computers will often not show events and a guessing game starts. Don’t let this happen. Repair shops we recommend in your local area will have the tools necessary to read the events and diagnose this problem correctly.

V6 Cayenne - Check Engine Light - Vacuum Leak - PCV Failure

Symptoms: CEL – Power Loss – Lean Condition Fault Codes – Increased Fuel Consumption

Symptoms: CEL – Power Loss – Lean Condition Fault Codes – Increased Fuel Consumption

An integral part of the emissions system on the Cayenne V6, is the PCV system that is designed to extract oil from gases in the crankcase. The oil is recycled to the oil sump, while the gas is passed through the combustion path to be burnt and cleaned by the catalytic converters.

When the PCV system fails on the V6 Cayenne engine, it will develop a vacuum leak and set a CEL for lean running conditions – un-metered air enters the intake path through the PCV system and the engine has a loss of power.

PCV System Failure – V6 Cayenne

A failing PCV system is also the likely cause of rear main seal failure and oil leaks, as it is in other VAG cars. Crankcase gas is not extracted well enough as the PCV fails. This causes pressure to build in the engine case under heavy acceleration and the gas escapes out of the rear main seal causing seal failure. This is commonly seen on all VAG V6 engines.

Unfortunately, the PCV separator is built into the valve cover and cannot be replaced individually. The repair requires the replacement of the whole valve cover assembly.

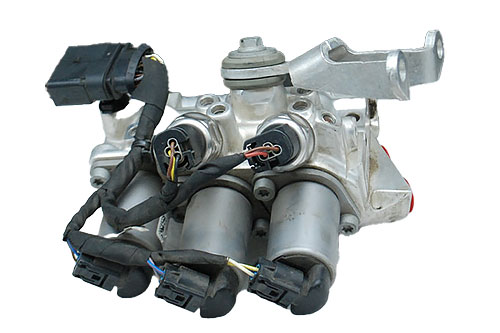

Check Engine Light - V8 Engine Failure - Cam Adjuster Bolts Break

Symptoms: CEL – Rough Running – Timing Faults

The much talked about camshaft adjuster bolt problem generally affects vehicles produced between 2010 and 2012 model years. The problem lies in the aluminum bolts that secure the timing chain sprockets to the camshaft adjusters.

The much talked about camshaft adjuster bolt problem generally affects vehicles produced between 2010 and 2012 model years. The problem lies in the aluminum bolts that secure the timing chain sprockets to the camshaft adjusters.

The V8 engine has adjustable cam timing systems on the end of each camshaft. The timing chain drives the adjuster, which varies the position and rotation of the cam based on engine performance demands. The adjuster is bolted to the end of the camshaft.

Timing Chain Adjuster Bolts Fail

Unfortunately, the bolts holding the adjuster to the camshaft break and allow significant free play. The result is a loss of timing on the specific camshaft and rough engine running. This sets a check engine light and fault codes for multiple items including camshaft position sensor, misfires, and cam to crank timing faults.

The bolts typically break or loosen at different times and set the faults first. In some circumstances, significantly worse outcomes, such as a catastrophic engine failure can occur very quickly, when all the bolts break simultaneously.

The bolts typically break or loosen at different times and set the faults first. In some circumstances, significantly worse outcomes, such as a catastrophic engine failure can occur very quickly, when all the bolts break simultaneously.

We experienced a V8 running very badly and setting faults for camshaft position sensor, misfires etc. Further investigation revealed that the intake camshaft was not rotating at all and all the bolts on the adjuster had broken.

Porsche V8 Engine Recall

Porsche was required to recall 2010 through 2012 V8 vehicles to correct this problem. If you are looking at a model in those production years, you should definitely check for evidence the recall work was completed. More information on the recall at http://www.camshaftadjusterrecall.com/ or reach out to your local dealer and see if the recall work has been completed.

No Start - Fuel Pump Failure - CEL - Random Multiple Misfire

Symptoms: Engine No Start, Start and Die, CEL Random Multiple Misfires, Loss of Power

Symptoms: Engine No Start, Start and Die, CEL Random Multiple Misfires, Loss of Power

Fuel pump failure on the Cayenne is very common. Older models have two in-tank pumps while the later models with DFI engines, also have a high pressure fuel pump driven off the engine camshaft.

Low Pressure Fuel Pump Failure

Failure of the in-tank pumps is very common. Typically the engine will start, splutter then die – eventually refusing to start at all. This is caused by the pump overheating very quickly and shutting off. Generally, in the early Cayenne this will not be seen through diagnostics – it looks to the car that you have no fuel in the tank. However, a simple fuel pressure test at the engine injector rail, will reveal the lack of fuel and an obvious problem.

Porsche updated both of the in-tank fuel pumps a number of times. So, when having this issue, we recommend replacing both of the pumps and associated filter in a single job. replacing fuel pumps is not an easy job and we recommend you use the skills of a professional Porsche repair shop to get this work done.

High Pressure Fuel Pump Failure

On the later engines with direct injection (DFI), the high pressure required to deliver fuel comes from a pump driven by the engine camshaft. A failure in the high pressure fuel pump has very similar symptoms to the failure of the in-tank pumps. However, there are sensors on the engine that report low fuel pressure conditions as fault codes to the diagnostic system and set a check engine light. Low pressure in the fuel system will usually begin as random multiple misfires and a loss of power under acceleration.

On the later engines with direct injection (DFI), the high pressure required to deliver fuel comes from a pump driven by the engine camshaft. A failure in the high pressure fuel pump has very similar symptoms to the failure of the in-tank pumps. However, there are sensors on the engine that report low fuel pressure conditions as fault codes to the diagnostic system and set a check engine light. Low pressure in the fuel system will usually begin as random multiple misfires and a loss of power under acceleration.

The key to solving this problem is diagnosing it correctly – the mechanical pump does fail quite commonly, however, if no fuel is being delivered from the tank because of a low pressure fuel pump failure, the high pressure pump will be unable to build fuel pressure for delivery to the injectors. This might look like a high pressure fuel pump problem when it isn’t! A good repair shop can accurately diagnose this for you.

Oil Level High or Low - Topping Off Oil Level

Symptoms: Warning Message Oil Level Too Low or High

Symptoms: Warning Message Oil Level Too Low or High

If you experience an oil level too high or too low message, be careful. First, there is no dipstick – brilliant idea most of the German car manufacturers have implemented. The oil level is measured electronically for accuracy. This is awesome, assuming the electronic measurement is accurate or is at the very least telling you the truth. There is no manual backup of the tried and trusted dipstick – so did you overfill or under fill? Or do you have a faulty sensor?

You have to be sure of which one before you take action. The only way to be sure is confirm the amount of oil in the engine by draining and measuring. We’ve experienced an oil reading that went down when we added a quart! Don’t be surprised if the oil level sensor is not telling the truth but, make sure you are certain that the oil level is correct before ignoring the sensor and replacing it.

Oil Top Off

The Porsche engines will naturally consume oil while you drive. Different driving styles and conditions will cause oil consumption to change. With the extended mileage between oil changes that manufacturers have opted for, it’s very likely the car will call for additional oil between scheduled service intervals. Most independent shops consider the extended mileage range between oil changes too extreme and simply a marketing gimmick.

The Porsche engines will naturally consume oil while you drive. Different driving styles and conditions will cause oil consumption to change. With the extended mileage between oil changes that manufacturers have opted for, it’s very likely the car will call for additional oil between scheduled service intervals. Most independent shops consider the extended mileage range between oil changes too extreme and simply a marketing gimmick.

If your Cayenne calls for additional oil, here’s what to do:

- Ideally, the engine should be at operating temperature

- The difference between the minimum and maximum reading is approx. 1 quart

- Do not add more than 1 quart at a time

- Remeasure the oil level after each quart added

- After adding a quart, drive the car for 5 to 10 mins before rechecking the level

- Oil reading is not instant and requires a drive cycle

Engine Cooling System

Coolant Pipes - Water Pump - Thermostat

Symptoms: Coolant Leaks – Steam From Under The Hood – Engine Overheating

A coolant leak can be deadly for any engine and especially on the Porsche Cayenne – overheating of the engine due to a loss of coolant very quickly does damage that could result in a total failure and an engine replacement being needed. The coolant pipe failure in the early Cayenne typically happened quickly and produced large amounts of steam from under the hood.

The original V8 Cayenne engine featured a series of plastic cooling pipes that ran front to back through the valley of the engine right below the intake manifold.

Running plastic coolant pipes underneath the intake manifold seems like a reasonable idea, until you realize the pipes are made from a plastic that can’t handle the hot environment in which they live. Once they degrade and a leak starts, it quickly speeds to a point where large clouds of steam can be seen billowing from under the hood when the engine is running – steam powered Cayenne!

Water Pump Failure

Water pumps and thermostats fail regularly. The water pump bearing that supports the drive shaft wears and consequently the shaft starts to wobble. This develops into a knocking noise and is often accompanied by a coolant leak on the front of the engine. Typically, this will also show up initially as a continual rise in engine temperature at idle speed, although when driving the Cayenne, it may maintain a normal temperature level.

Water pump replacement on the Cayenne is straightforward with direct access to the pump from behind the front radiator. This is also the location of the thermostat, which also fails regularly and replacing both at the same time makes sense.

Thermostat Failure – Overheating

The Cayenne thermostat is electronically controlled and reports a fault when a failure occurs. A failed thermostat that is stuck open is not so bad, as the engine will typically run too cold. On the other hand, a thermostat that fails in the closed position, can quickly be very detrimental to the engine and overheating can occur rapidly.

The Cayenne thermostat is electronically controlled and reports a fault when a failure occurs. A failed thermostat that is stuck open is not so bad, as the engine will typically run too cold. On the other hand, a thermostat that fails in the closed position, can quickly be very detrimental to the engine and overheating can occur rapidly.

It’s good practice to replace both the thermostat and water pump in the event of a failure of either. In addition, should a leak have occurred on the front of the engine, it’s important to check the condition of the drive belts and replace if necessary at the same time.

Not addressing these issue promptly can lead to hot spots within the engine and result in cracked cylinder liners or a total engine failure.

Continual Coolant Leaks - Front & Rear Engine - 957 V8

Symptoms: Loss of Coolant, Flashing Coolant Light

The 957 Cayenne has a series of coolant pipe connectors that are glued into their aluminum housings – great idea! Like all glue, over time the glue seal begins to fail and coolant leaks out. There are two likely spots for this to occur – the front of the engine or the rear of the engine close to bell housing and the transmission to engine joint.

Front Engine Coolant Leak

The leak at the front of the engine is most likely from the upper front coolant pipe, which slips out of its housing when the glue fails. Porsche revised the design of the replacement part to be bolt in, so the problem should not return. This issue is common and typically runs about $500 in parts. Most 957 Cayenne models have already completed this work.

Rear Engine Coolant Leak

Rear Engine Coolant Leak

The leak at the rear of the engine is much more of an issue. Almost all V8 Cayenne models experience a failure in a coolant hose connector at the back of the engine that is close to the firewall. You’ll see a low coolant light and a puddle of coolant in the middle of the car, just behind the front wheels.

Leaking Coolant Tube Inserts

The rubber cooling hose is clamped to an aluminum insert that sits in the housing that distributes coolant between the two cylinder heads. The glue fails on the aluminum insert and coolant leaks out. The replacement part is updated with a screw in insert for the rubber hose to connect to. Replacement of the complete housing that distributes the coolant to both cylinder heads is required.

Replacing the Coolant Distribution Tube

Exhaust

Exhaust Rattle and Catalytic Converter Inefficiency Faults - CEL

Symptoms: Exhaust Rattle Under Acceleration

Symptoms: Exhaust Rattle Under Acceleration

Many Cayenne models are starting to experience failure of their catalytic converters and mufflers. In many cases, the main exhaust header pipe leading to the cat converter will crack and fail completely.

Initially, you’ll start to notice a rattle. This is caused by the catalytic converter coming apart internally. While annoying, it’s also potentially destructive – a partial blockage in the exhaust can cause the engine to not run or worse, it will cause immense heat to build at the blockage point. Seeing a catalytic converter glowing bright orange under a Cayenne is quite disconcerting!

The disintegration of the catalytic converter typically causes a check engine light with emission fault codes associated with converter inefficiency. This means you can’t pass the emissions test and in some states that means not driving the car at all.

Transmission and All Wheel Drive

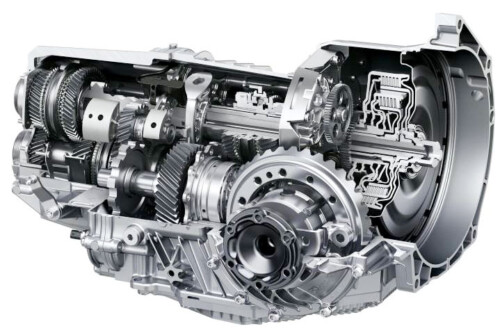

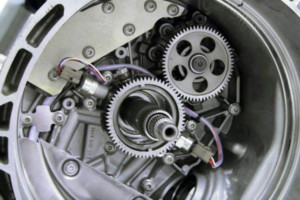

Heavy Gear Changes & Noisy Transmission - Tiptronic

Symptoms: Heavy Gear Shifts or Banging Sound From Transmission

Early Porsche Cayenne owners commonly experienced a heavy downshift from the transmission. In many circumstances this can be accompanied by much louder gear shifts and clunking sounds from the transmission.

The problem is often mis-diagnosed as a physical failure in the transmission itself, when the more likely cause is in fact the valve body assembly within the transmission. The valve body is an electro-mechanical device the redirects the pressurized transmission fluid through a valving system to enable the physical gear changes. Failure of the mechanism can lead to some wild gear shifts and unpleasant noises.

Thankfully, with the Cayenne, the valve body assembly is readily available and replacing it typically saves the transmission. In many cases normal smooth gear shifts are returned with replacement of the valve body assembly.

Transfer Case - Vibrations Under Acceleration or When Turning at Low Speed

Symptoms: Vibration Under Acceleration or During Low Speed Tight Turns

Symptoms: Vibration Under Acceleration or During Low Speed Tight Turns

Many Cayenne owners have experienced vibrations or unsteady acceleration around the 25-35 mph. This is usually subtle initially, but gets steadily worse, especially when moving forward at low speed with the wheels turned tightly. Sometimes, this can also show up as jerking when the PDK is going through 2nd to 3rd gear changes and accelerating between 30-50mph.

The problem stems from the transfer case in the four-wheel drive system and is a regularly reported issue.

Transfer Case Problems

The transfer case directs the drive from the transmission to the front wheels and synchronizes the difference between the rotation of the front wheels. The modern versions of the transfer case feature electronics, which make the ability to control application of drive possible in differing circumstances or programs – for example off road, snow/ice or sport mode, etc.

Wear in the transfer case causes a mismatch between the intended wheel speeds during acceleration and the actual wheel speeds. This subsequently shows up as a vibration under acceleration or a jumping or skipping feeling at extreme steering lock.

Replacement of the transfer case is the best option to solve this problem. While the transfer case has been revised a number of times, this issue appears to continue to plague the Cayenne. Seemingly as a result, Porsche announced an extension to the warranty period covering the transfer case.

Clunking Sound on Acceleration - Drive Shaft Support Bearing Failure

Symptoms: Clunking or Banging Down Center of Car Under Acceleration

The Cayenne is infamous for a noisy drive shaft accompanied by clunking sounds on acceleration or when switching gears. This is usually caused by a failure in the driveshaft support bearing.

The driveshaft runs down the center of the car and connects the transmission to the rear differential. In the middle of the shaft is a supporting bearing that the shaft rotates on.

When the center support bearing fails, the shaft wobbles, vibrates and thumps during acceleration. You’d be hard pressed to find an early Cayenne that hasn’t experienced this problem or currently be somewhere close to experiencing it again. Porsche’s replacement for the bearing wasn’t much better than the original – even the early Macan experienced the same problem!

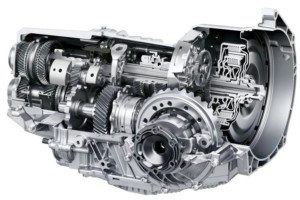

PDK Issues - Transmission Faults

Symptoms: PDK Failure Light, Rough Gear Changes, Transmission Faults, Emergency Transmission Run Warning on Dash

The Porsche-Doppelkupplungsgetriebe – which translates to Porsche double-clutch transmission or PDK (now that’s when you really need an acronym!) has been the subject of a number of failures. Porsche Cayenne owners have experienced failure of the PDK transmission. For more information, see our page dedicated to PDK failures, symptoms, and faults with potential resolutions.

The PDK is an automated manual transmission. Two units matched together – a manual transmission rear section and automated dual clutch front section. The manual transmission rear section is very solid and reliable. Most issues occur with the electronic and hydraulically controlled clutch section at the front of the transmission. Physically, the PDK is a ZF transmission unit that has been around for a number of years. VAG took multiple versions of the transmission and personalized them for their various car ranges. Porsche adapted the software and labeled their version PDK.

There are a number of ways in which the PDK in the Cayenne can fail. Most show up as a collection of warning lights on the dash and an eventual refusal to do anything. The only viable solution for most people is the replace the PDK – this is very expensive. However, much of the need for replacement of the PDK comes from a lack of understanding, unavailable parts and an unwillingness to dig deep.

Components and Failures

Transmission Control Module – TCM

The connection to the car and communication of instructions to the transmission, come from an external module called a transmission Control Module (TCM). While this rarely has issues, it can become confused and has been the subject of a number of software revisions. Re-flashing the TCM doesn’t usually solve problems, but ensuring you have the latest software revision can’t hurt. This is where diagnostic faults are stored.

The connection to the car and communication of instructions to the transmission, come from an external module called a transmission Control Module (TCM). While this rarely has issues, it can become confused and has been the subject of a number of software revisions. Re-flashing the TCM doesn’t usually solve problems, but ensuring you have the latest software revision can’t hurt. This is where diagnostic faults are stored.

Mechatronic Unit – Valve Body

The TCM sends instruction to the Mechatronic unit or valve body inside the transmission. The Mechatronic unit is a complex series of electronics, hydraulic valves and sensors. These devices are managed by a control module attached to the Mechatronic unit. This is the system which enables gear changes and controls the transmission functionality.

Problems with the Mechatronic unit vary, but commonly include failure to select gears, rough gears changes, etc. The physical components of the transmission are robust, so this unit is often the most economical place to start for most issues.

Internal Sensors

Connected to the Mechatronic unit are a number of sensors throughout the transmission. These determine the operating conditions within the transmission. For example, the temperature of the fluid, the rotational output speed, hydraulic clutch pressure and movement of gears selectors. Failure of these sensors is very common. Early on, Porsche routinely replaced the wiring and trans temp sensor in most of the PDKs.

Connected to the Mechatronic unit are a number of sensors throughout the transmission. These determine the operating conditions within the transmission. For example, the temperature of the fluid, the rotational output speed, hydraulic clutch pressure and movement of gears selectors. Failure of these sensors is very common. Early on, Porsche routinely replaced the wiring and trans temp sensor in most of the PDKs.

However, the problem did not go away and has re-occurred on the same transmissions further down the road. The temp sensor problem can show up on almost any model with a PDK. See our PDK problems page for more detail on the sensor problems.

Clutch Pack

The clutch pack has proven to be very robust and generally does not fail with normal use. Over extended mileage this will become a wear component that will need to be replaced. The failures of the clutch that have occurred, are usually on performance enhanced engines delivering too much torque for the clutch plates. At higher torques, the clutches slip resulting in highly accelerated wear and early failure.

The clutch pack has proven to be very robust and generally does not fail with normal use. Over extended mileage this will become a wear component that will need to be replaced. The failures of the clutch that have occurred, are usually on performance enhanced engines delivering too much torque for the clutch plates. At higher torques, the clutches slip resulting in highly accelerated wear and early failure.

The PDK transmissions in the later cars are very complex and the technology involved is a closely guarded secret. Technicians at Porsche are not required to dissect the transmission and make repairs. They will replace the Mechatronic unit, but often they just replace the transmission as a whole.

Don’t Replace Your Porsche PDK Transmission – It Can Easily and Economically Be Repaired

Don’t Replace Your Porsche PDK Transmission – It Can Easily and Economically Be Repaired

Expert Porsche PDK Transmission Repair Service

The good news is the Porsche PDK transmission is fully repairable for a fraction of the cost of replacement. And in more good news, repairs of the PDK transmission have led to expert knowledge to be able to recommend additional preventative maintenance that can help avoid the common issues that arise with the PDK.

Recommended Porsche PDK Repair Specialist

We have partnered with MC Squared Autosport and highly recommend their Porsche PDK transmission repair service.

Electrical System Faults

Porsche Communication Management (PCM) Issues

Symptoms: Cayenne PCM unit restarting every 2-3 minutes, map not loading, loads in wrong language, loads just the Porsche logo screen, turns on and off randomly etc.

Who hasn’t had an issue with the PCM system in their Cayenne?

Who hasn’t had an issue with the PCM system in their Cayenne?

Many Cayenne owners have reported all sorts of random and weird behavior from the PCM system and in particular updates seem to often be the main offender. Many are convinced that various software updates resulted in unstable working conditions. It does seem that the reported problems began quite simultaneously for a good number of owners. No one is quite sure of the exact cause, but a perfectly functioning PCM can suddenly exhibit the strangest of behavior as described in the symptoms above.

Defining the Issue with the Cayenne PCM

The problems with the PCM can really be categorized in to two groups.

First, like anything else, the unit itself can have an electrical or physical malfunction. Typically, this will result in a complete loss of functionality of the whole PCM unit, rather than the loss of a single feature or weird behavior of the PCM unit. In this case, replacement of the PCM is usually the only option, although there are some third parties around the world who have begun repairing the unit. Not an option for the dealers – they have to replace it and the cost is quite high.

For the second set of Cayenne PCM problems that generally fall into the strange behavior category, an old-fashioned Ctrl Alt Del seems to resolve most issues. Some will remember when it was necessary to do this a couple of times a day to a Windows PC, but in this instance, the PCM usually recovers well to an initial start point and then functions normally.

For the second set of Cayenne PCM problems that generally fall into the strange behavior category, an old-fashioned Ctrl Alt Del seems to resolve most issues. Some will remember when it was necessary to do this a couple of times a day to a Windows PC, but in this instance, the PCM usually recovers well to an initial start point and then functions normally.

Resetting The PCM System in Your Cayenne

It is important to note that what you are doing here is resetting the system back to the original factory defaults prior to your Cayenne being delivered to its first customer. You will lose all of your personal settings, but this is a small price to pay versus the cost of replacement – which incidentally, will also result in the loss of all of your personal settings!

The following video explains how to perform a reset of the PCM:

No Start - Steering Faulty - KESSY

Symptoms – Steering Faulty Message On Dash – Car Will Not Respond to Key

This problem happens when a convenience system becomes inconvenient!

This problem happens when a convenience system becomes inconvenient!

Porsche added the KESSY system to the Porsche Cayenne to enable keyless entry and driving as a convenience for the driver or second driver with a different key. Unfortunately, the initial system is less than reliable and has a reasonable high failure rate in older Cayenne models.

Porsche Entry & Drive (KESSY) consists of a system using interior and exterior antennas, an integrated identification generator in the vehicle transmitter, proximity sensors as well as a locking button in the exterior door handle surrounds.

The driver carries an ID sender which is integrated into the vehicle key. When the system sees the signal from the key it can unlock the doors, set the seats, and hvac to the appropriate settings for each driver thereby personalizing the experience.

Steering Lock Problems and Resolutions

Steering Lock Problems and Resolutions

Kessy also encompasses the security system for the alarm and steering lock systems.

Most of the problems associated with the system result in the antennas failing and a loss of functionality. Most people ignore this or don’t even realize it happened. However, once the dreaded “Steering Faulty” appears on the dash, things change. The steering wheel is now locked and the car is unresponsive to the key. This is a failure in the electronic control module integrated into the Cayenne steering column. The car is literally stuck where it is until you have it towed.

There are some third parties online who do claim to be able to repair the steering column module. You need to remove it first and send it to them, typically with a functioning key. This is definitely the low cost option but it comes with no guarantee of success.

Random Airbag Fault - Airbag Light

Symptoms: Airbag Light Flashes or Stays On and Goes Off Randomly

Many early model Cayenne drivers have noted that their airbag fault light flashes randomly. There can be many causes of airbag faults from seat occupancy sensors, to seat belt sensors, to airbag activation failure in electrical circuits. As with any safety system, it’s important to accurately diagnose the problem and we recommend a Porsche specialist.

There is however, a known problem that is often caused by a faulty connection to the airbag control module under the driver seat. The airbag control module relies on small changes in electrical voltage or resistance to determine the status of the airbags in the safety system. Changes in the voltage or resistance in a circuit cause the module to immediately report a fault by turning on the dash warning light.

Corroded Electrical Connector Issues

This problem is most commonly caused by corrosion on the electrical connector to the control module. Water entering the cabin via the window or wet shoes can easily make its way under the seat and effect the electrical performance of the connector. Check to see if water has damaged any of the electrical pins and plugs. In many cases, the connector and control module will need to be replaced.

Water Leaks - Blocked Drains and Electrical System Damage

Symptoms: Electrical System Failures – Strange Electronic Behavior – Water in The Cabin or Trunk

Symptoms: Electrical System Failures – Strange Electronic Behavior – Water in The Cabin or Trunk

Part of the annual maintenance schedule for Porsche vehicles is the clearing of roof drains. However, this has been overlooked and not carried out in many circumstances. The resultant damage from blocked roof drains can be extensive.

Porsche Sunroof Drains

Your Cayenne has 4 drains that take water away from the roof and send it through a tube to an exit point low on the bodywork. These drains can become blocked with debris from leaves, dust and general road dirt. They can also fail or split. Once the drain is blocked, water backs up in the pipe until the pipe gives way or it finds another way out. Unfortunately, the exit point for the water typically seems to be close to sensitive electronic equipment.

Finding Water Leaks in Your Cayenne

Finding Water Leaks in Your Cayenne

If you discover water in the trunk or inside the passenger cabin by the front windshield, blocked or failed roof drains are normally the root cause. The water can very quickly enter the wiring harness, electrical connectors, and control modules near the leak. The replacement of control modules is expensive and often requires additional security programming. Water entering the trunk can also damage the trunk mechanism, exterior lighting, and the trunk interior.

Prevention of the Water Leak Problem

Clearly, the prevention of the blocked drain is the solution to this problem. It’s essential that during the maintenance service intervals, the roof drains are cleared of debris. Where you service your Porsche can make a world of difference! We recommend you use a Porsche specialist.

Porsche has recently settled a class action lawsuit filed for the water leak problem. You may benefit from that.

HVAC System

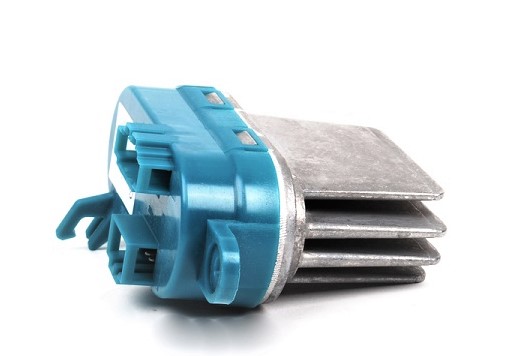

Noisy or No Function from HVAC Fan

Symptoms: HVAC Fan Stops Working, Single Speed Only or Noisy Operation

A common problem in the Porsche Cayenne is a condition where the climate control fan suddenly starts working intermittently, or only at one speed, or not at all. It may also become excessively noisy.

Blower Motor Regulator

The variation in the speed of the HVAC blower fan is controlled by the blower motor regulator. Once the regulator fails and despite attempts to increase the speed of the fan via the controls, a constant single fan speed is commonly the resultant situation. Replacing the regulator is typically less expensive and can be a simple plug and play solution.

Blower Motor Failure

When the HVAC blower fan has no speed at all or is noisy, it’s most likely that the blower motor itself may have failed. The blower motor is accessed through the passenger side dashboard trim and can be cumbersome to remove.

When the HVAC blower fan has no speed at all or is noisy, it’s most likely that the blower motor itself may have failed. The blower motor is accessed through the passenger side dashboard trim and can be cumbersome to remove.

It makes sense to replace the fan and the regulator at the same time. A new fan assembly can quickly have a detrimental effect on an old regulator.

Brakes - PSM Faults

ABS PSM Failure - No Engine Start

Symptoms: ABS or PSM Warning Light – No Start

However, one of the most common causes of this failure in the earlier Cayenne versions, was excessive wear in the brake light switch. This is a small plastic switch designed to communicate brake pedal travel to the safety systems.

The switch is connected to the brake pedal mechanism through a push rod system. Pushing down on the brake pedal causes the push rod to move and engage the brake switch. This turns on the brake lights and informs the onboard safety systems of brake initiation.

Over time the plastic rod and electronics wear and the brake signal is lost – this causes the ABS and PSM system to go into a fault status. It can also cause a failure of brake lights and a no start situation. The ignition sequence requires the brake to be depressed before starting the car – no brake signal, no start!

PSM Failure Message

Here’s What to do When You See PSM Failure on Your Porsche Dashboard

Here’s What to do When You See PSM Failure on Your Porsche Dashboard

PSM failure can be a common issue on the Cayenne, however, because the system is so interconnected, the message PSM failure can be deceptive. The PSM per se has not itself failed. The likelihood is a single sensor or component connected to the system is broken. The interconnection of the systems can result in the reporting of multiple faults and cause significant confusion to the untrained. Commonly a single sensor failure will report multiple faults in various systems. Proper diagnosis of the root cause will save you money versus part replacement guess work.

9YO Cayenne models had a batch of faulty wheel speed sensors that often caused this issue. We recommend the replacement of all four wheel speed sensors if this happens.

Brake Booster Fault

Symptoms: Brake Booster Fault – Dash Message, Harder Brake Pedal

Symptoms: Brake Booster Fault – Dash Message, Harder Brake Pedal

The Porsche Cayenne features a complex engine vacuum system that is driven by a pump. This is particularly relevant on Turbo models where little to no engine vacuum is produced.

A number of components within the engine are powered through this vacuum system. The most common fault set through a failure in this system is that of the brake booster fault.

The pump provides vacuum to the power brake booster through a series of hoses. The level of vacuum is monitored through a sensor and a drop in vacuum can cause the sensor to report the fault to the dashboard. Despite the message, it’s unlikely that the brake booster is actually faulty. Typically the problem lies in a lack of vacuum to the booster as a result of a crack in one of the vacuum lines.

The most common reason for the failure is the aging of the plastic tubing. Over time, the hard plastic tubing heats and cools rapidly. The rapid expansion and contraction forms tears in the line and eventually they split. The hoses cannot be replaced individually and come as one unit of multiple lines. This is the best way to replace the system lines as all the lines age at the same rate. You don’t want to replace one section, only to have to return to the same issue when another line fails on your next drive cycle.

Assuming all the lines are in good shape and hold vacuum, then the problem may well lie with either the vacuum pump itself or the sensor. These are straight forward to replace and are a common wear item. A complete lack of vacuum should be fairly obvious to diagnose.

Assuming all the lines are in good shape and hold vacuum, then the problem may well lie with either the vacuum pump itself or the sensor. These are straight forward to replace and are a common wear item. A complete lack of vacuum should be fairly obvious to diagnose.

Fault Electric Parking Brake Message

This message relates to the ability for the electrical system to operate the parking brake. The parking brake is applied via electric motors.

This message relates to the ability for the electrical system to operate the parking brake. The parking brake is applied via electric motors.

Here’s what to do – Hopefully at this stage the parking brake is off. Do not attempt to operate it. If the parking brake is stuck on, then a painfully expensive tow charge will likely apply!

Suspension and Steering

Chassis System Failure - Suspension Problems - PASM Fault

S ymptoms: Chassis System Failure Message, Uneven Ride Height, PASM Fault

ymptoms: Chassis System Failure Message, Uneven Ride Height, PASM Fault

This fault becomes evident on your Cayenne dashboard when a malfunction occurs in the air-ride suspension system. The system has a number of components, but generally, only one failure indicator. Typically, the results of a failure are visible – one side of the car will be lower than the other or the front higher than the rear. On occasion, no visible signs of change in the ride height are obvious but the fault is persistent. In colder climates, the fault can be sporadic initially, based on air temperature.

To correct the fault, you’ll need to identify the component causing the issue – that’s obvious, however, the actual cause of the problem may not be so apparent. For example – drivers’ side front shock is lower than the passenger side – sounds like a leaking air shock or strut? Maybe, but it could also be a ride height sensor, leaking hose, faulty valve block or bad electrical connector!

Diagnosing Air Ride Suspension on a Cayenne

Components and Common Failures

Air compressor

The air compressor supplies the system with compressed air. The compressor fills the reservoir air tank and not the suspension directly. The compressor is designed to run in short bursts to top off the tank.

The air compressor supplies the system with compressed air. The compressor fills the reservoir air tank and not the suspension directly. The compressor is designed to run in short bursts to top off the tank.

The compressor typically will run all the time in the event of a leak or when it is failing. Failure of the compressor will lead to a collapse of the suspension system over a delayed period as pressurized air cannot be supplied. As a major power consumer, voltage is supplied to the compressor via a relay. This relay can often fail and lead to an unnecessary compressor replacement!

Air tank

The air supply tank is the least likely area of failure. This simply stores the compressed air to enable enough volume to be delivered quickly to correct the vehicle ride height. The tank supplies air to the system via the valve block – a hole in the line from the tank to the valve block will cause a system wide failure.

Valve Block

Compressed air is supplied to the valve block from the air tank. The valve block is an electro-mechanical device that routes pressurized air to the individual system components per instructions sent from the control module. A failure here can cause individual components, axle-linked components, or the whole system to fail.

Compressed air is supplied to the valve block from the air tank. The valve block is an electro-mechanical device that routes pressurized air to the individual system components per instructions sent from the control module. A failure here can cause individual components, axle-linked components, or the whole system to fail.

Air lines or hoses

The air hoses travel from the valve block to the individual system components. Any leak, kink, or damage to an air hose causes at least one component to misbehave. Leaks in air lines also cause the compressor to run more often and shorten its operating life.

Front Air Shocks or Struts – Rear Air Spring

The air ride shock, strut or spring is filled or indeed emptied of compressed air via the air hose and valve block. Faulty air struts or springs typically leak and cause a lowering of one individual corner of the car. Two failing at the same time is unusual, so if you have a lower than normal ride height across one axle, do not assume leaking struts – see level sensors below. Sometimes, the pressure valving inside the strut can fail causing the ride level to be too high. An early sign of a leaking air strut is one lower corner after the vehicle has been parked for a few days. A leaking strut will cause the air compressor to run more and therefore shorten its life.

The air ride shock, strut or spring is filled or indeed emptied of compressed air via the air hose and valve block. Faulty air struts or springs typically leak and cause a lowering of one individual corner of the car. Two failing at the same time is unusual, so if you have a lower than normal ride height across one axle, do not assume leaking struts – see level sensors below. Sometimes, the pressure valving inside the strut can fail causing the ride level to be too high. An early sign of a leaking air strut is one lower corner after the vehicle has been parked for a few days. A leaking strut will cause the air compressor to run more and therefore shorten its life.

Electrical connectors

Each of the suspension components has an electrical connector. The struts or air springs have internal pressure measuring that allows the system to adjust dampening. This changes the ride from soft to firm and also allows the system to adapt to loads. this is also the basis of the PASM system to enable ride changes from sport to comfort.

The electrical connectors can become corroded or greened in some circumstances. This causes the system to report malfunctions but typically does not affect ride height. Ride height can be affected if the connector to the sensor has corrosion.

Ride Height Level sensors

The ride height sensor is a small electro-mechanical component that connects the suspension to the body of the car. A small plastic arm translates vertical vehicle movement into rotational movement in the sensor. Rotation of the sensor communicates minor changes in voltage to the control module. Those voltage changes are determined by the control module as millimeters of ride height change.

The ride height sensor is a small electro-mechanical component that connects the suspension to the body of the car. A small plastic arm translates vertical vehicle movement into rotational movement in the sensor. Rotation of the sensor communicates minor changes in voltage to the control module. Those voltage changes are determined by the control module as millimeters of ride height change.

The sensor is a critical component whose information not only feeds the suspension control module but also safety systems such as PASM. Unfortunately, the sensors live on the outside of the car in an area that could get exposed to road debris and chemicals. Failure of these sensitive components is inevitable.

Ride height sensor faults can be fun! A dead sensor is straightforward to diagnose – no signal. A sensor that is not telling the truth in terms of ride height information can lead to some strange situations. Because a ride height signal is still reaching the control module from a faulty sensor, action is taken based on that faulty information. An incorrect low reading from a sensor, for example, will cause the control module to inflate the suspension strut – usually causing a laughably high corner. Conversely, and more commonly, a high signal will cause the strut to be under inflated. This looks like a leak and is commonly mis-diagnosed.

Suspension Control Module

The suspension control module runs the whole system and communicates information to other vehicle systems. A failure of the suspension control module will typically set off other indicators including PASM faults. The control module is one of the least likely items in the system to fail. A typical failure will be a complete shutdown of the suspension. Control module failures rarely cause part system failure.

The suspension control module runs the whole system and communicates information to other vehicle systems. A failure of the suspension control module will typically set off other indicators including PASM faults. The control module is one of the least likely items in the system to fail. A typical failure will be a complete shutdown of the suspension. Control module failures rarely cause part system failure.

Switches

Switch failure is commonly overlooked. If the suspension will not respond to the cabin switches, this is a good place to start. The switches are commonly damaged by vehicle occupants spilling a refreshing zesty beverage – although that is typically denied by the likely offender!

Electronic Power Steering Fault

Later Cayenne models feature electronically assisted power steering. Fault messages associated with the power steering typically indicate a loss of steering assistance or support and suggest you can drive on. This means the steering will feel heavy and requires more effort. This can be a potentially dangerous situation and should be diagnosed as quickly as possible.

Later Cayenne models feature electronically assisted power steering. Fault messages associated with the power steering typically indicate a loss of steering assistance or support and suggest you can drive on. This means the steering will feel heavy and requires more effort. This can be a potentially dangerous situation and should be diagnosed as quickly as possible.

Failure of the electronic steering rack is not that common. These faults are normally caused by power supply failure through a faulty relay.

Chassis System Fault - PDCC

Symptoms: Chassis System Fault Message, Suspensions Noises, Loud Noise from PDCC Pump, Fluid Leaks

Symptoms: Chassis System Fault Message, Suspensions Noises, Loud Noise from PDCC Pump, Fluid Leaks

This fault becomes evident on your Cayenne dashboard when a malfunction occurs in the Porsche Dynamic Chassis Control System – PDCC. The system has several components, but generally, only one failure indicator.

The PDCC is a hydraulic system operated by a pump and is designed to reduce lateral body movement during cornering maneuvers. It can also mitigate the lateral instability of the vehicle on uneven surfaces. This is done by pushing fluid into and out of the chassis stabilizers or anti-roll bars.

PDCC Components That Fail

PDCC Hydraulic Pump

PDCC Hydraulic Pump

The PDCC pump is clearly an integral part of the system. Without the pump constantly providing the right pressure, the system quickly fails. The fluid reservoir for the pump is a maintenance item as the filter for the system is included within the reservoir. The pump is expensive, but often failure of the pump is caused by a system leak – just replacing the pump if you have a leak, can lead to quickly needing to replace the pump again!

PDCC Valve Body

The axle specific valve body controls the flow of fluid to the relevant side of each axle. The valve body can fail for several reasons – the most common being debris in the fluid from a lack of maintenance.

PDCC Pressure Sensor

The PDCC pressure sensors determine the pressure in each line via the system valve body. These sensors can often become corroded and fail.

Leaking Lines and Connections

Many of the problems associated with the PDCC are caused by corrosion of the system lines or connections to the active suspension components. The corrosion of a supply line can cause a leak, loss of pressure, and eventually failure of the pump. The lines and connections are particularly susceptible to road chemicals used in the northern states.

Replacing Components and Bleeding the PDCC System – Correct Procedure Required

The PDCC system requires a specific bleed procedure to ensure the integrity of the system after replacement of components or maintenance. The procedure requires system activation via a PIWIS diagnostic computer. Failing to bleed the system correctly can be very expensive. We recommend you work with a Porsche specialist if you have a PDCC problem.

Still Can’t Find An Answer? – Contact Us For More Help

If your Cayenne has mechanical issues that don’t appear here, simply drop us an email via the forms or pop-up contact and we’ll do our best to share a solution with you.