Porsche Boxster Common Problems

Common Reliability or Mechanical Issues Diagnosed on the Porsche Boxster

All You Need to Know About Porsche Boxster Common Problems, Concerns, Reliability, and Mechanical Issues

All You Need to Know About Porsche Boxster Common Problems, Concerns, Reliability, and Mechanical Issues

Listed below by symptom are Porsche Boxster common mechanical problems with their most likely resolutions explained. These are the most frequent Boxster problems and mechanical issues for the 986, 987, 981, and 718 that were diagnosed by our repair shops.

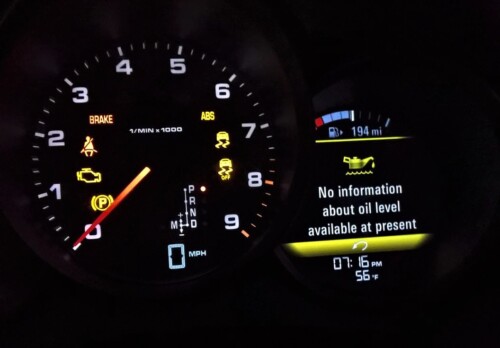

Here’s What to do if You See Warning Lights, Messages, or Symbols on Your Porsche Boxster Dashboard

Here’s What to do if You See Warning Lights, Messages, or Symbols on Your Porsche Boxster Dashboard

Often a Porsche Boxster common problem or mechanical issue will be associated with a dashboard warning light, message, or symbol. Be aware, there are more problems than there are warning lights or symbols and often the lights and messages are not always that clear. In our Dashboard Warning Lights, Messages, and Symbols section, we recommended what action to take when you see a warning on your Porsche dashboard.

Could Maintenance Solve a Porsche Boxster Problem?

Maintenance rarely solves a problem. However, neglecting maintenance can cause issues – check your last service update with our recommended Boxster maintenance schedules.

Scanned Your Boxster and Read Diagnostic Codes?

Scanned Your Boxster and Read Diagnostic Codes?

Check engine light? Have you scanned your Boxster and are now not sure what to make of those OBD codes? Our article on how to interpret and make sense of those fault codes may help. The following sections identify common problems through symptoms. If you have scanned your Porsche OBD2 system and have identified fault codes, go to our Porsche powertrain fault code page to get additional fault code descriptions.

Can’t Find An Answer Below? – Contact Us For Help

If your Boxster has mechanical issues that don’t appear here, simply drop us an email via the forms or pop-up contact and we’ll do our best to share a solution with you.

Porsche Boxster Reliability

The fact the car is a fine tuned Porsche can often lead to what would normally be deemed expensive repairs when compared to domestic or Japanese coupes. You’re driving a Porsche, so the reliability and repair cost comparison is invalid in our opinion! In general, the later Boxster has no scary common issues that should ever stop you owning and enjoying one. Earlier versions can have significant engine problems and the later versions can also experience PDK transmission issues. Most of these issues can be avoided with care and easily repaired.

Clicking on a heading below gives you more detail.

Porsche Boxster Common Problems by Symptom – 986 | 987 | 981 | 718

Engine

Rear Main Seal Oil Leak

Symptom: Oil Leak Between Engine & Transmission Joint

One of the most common, misunderstood and potentially destructive issues on the Boxster, is an oil leak from the rear main seal. A leaking rear main seal appears through the bell housing joint between the center of the engine and transmission joint. The leaking seal will quickly destroy a clutch in a manual car if not addressed promptly and can be a sign of other issues.

Some caution – vehicles that are stored often display a weep/leak from the seal during storage or at the initial startup in the spring. The seal needs the heat of driving to remain sealed efficiently, so in some circumstances the leak can slowdown or stop during the driving season. Replacing the seal requires the removal of the transmission and in a manual car, replacement of the clutch at the same time is a good choice.

The seal does dry over time and can leak, however, there are other potential issues that could also cause the seal to leak (see Air Oil Separator below). Causes of the seal failure should be checked thoroughly by a competent shop before you proceed to replace the seal.

Common Oil Leaks

Porsche Boxsters have a number of common sources for leaking oil. Some of the most common include rear main seal (see below), valve covers, spark plug seals and oil cooler seals. Less common are leaks from the cam seals and scavenger oil pump seal.

Symptom: Oil Drips on Floor Below Engine

Valve cover leaks are obvious and fairly straightforward to fix on most models. The valve covers do not have a gasket – instead a liquid gasket sealer is used. The time consuming part is removing the old gasket sealer from the valve cover to ensure a good seal for the replacement. Valve cover leaks can make their way onto the exhaust headers and lead to a burning smell or worse.

Valve cover leaks are obvious and fairly straightforward to fix on most models. The valve covers do not have a gasket – instead a liquid gasket sealer is used. The time consuming part is removing the old gasket sealer from the valve cover to ensure a good seal for the replacement. Valve cover leaks can make their way onto the exhaust headers and lead to a burning smell or worse.

Symptom : Misfires CEL or Oily Spark Plugs

Spark plug tube seals are also prone to leaking – leaks from the spark plug tube seals can be frustrating. Often, you wont see the oil initially, as it’s sealed in by the coil on top of the spark plug. The tube fills with oil and causes misfires by destroying the plug and the coil. If you see oil on a plug or coil, always replace the seals.

The upper seal can be replaced when removing the valve cover. The lower seal leaking is less common but more of an issue and requires removal of the camshafts.

Oil Drain Plug Leak

This should really never happen and is usually the result of a failure to replace the drain plug or its seal.

Air Oil Separator (AOS)

Symptoms : Smoke From Exhaust, Oil In Intake, Rear Main Seal Leak

Symptoms : Smoke From Exhaust, Oil In Intake, Rear Main Seal Leak

Bad rear main seal or something else causing the problem?

An integral part of the emissions system, the Air Oil Separator (AOS) is designed to extract oil from gases in the crankcase. The oil is recycled to the sump, while the gas is passed through the combustion path to be burnt and cleaned by the catalytic converters. The AOS has caused numerous issues on Porsche engines and is an item to be closely monitored.

As the membrane in the AOS fails, oil is sucked into the air intake. Initially this can show up as a check engine light for fuel adaptations with oil being deposited on the o2 sensors causing emission faults.

Of course, once it fails completely, the resultant burning oil produces huge clouds of white smoke – this is fairly obvious. At that point, it is clear what needs to be done. However, replacing the aos sooner rather than later can be a good precaution against other failures.

A failing air oil separator (aos) is the likely cause of rear main seal failure and oil leaks, as it is in other VAG cars. Crankcase vacuum exceeds the normal range in the engine under heavy acceleration and sucks in air damaging the rear main seal. This is commonly seen on Audi engines as well.

A failing air oil separator (aos) is the likely cause of rear main seal failure and oil leaks, as it is in other VAG cars. Crankcase vacuum exceeds the normal range in the engine under heavy acceleration and sucks in air damaging the rear main seal. This is commonly seen on Audi engines as well.

A failing aos also causes too much oil to pass into the intake and will force the engine management to adjust fuel mixtures to compensate. The changing mixture can cause over fueling and lead to other more significant problems – See smoke at startup below.

For cars that go to the track on a regular basis, a Porsche Motorsport AOS upgrade is highly recommended. The upgraded aos features a doubling in size of capacity for scavenging and is less prone to sucking up oil during high speed cornering.

Puff of Smoke On Cold Engine Startup

A quick puff of smoke as you start a cold engine is not uncommon, especially on the Porsche flat six engine in the Boxster. There are many theories and various thoughts as to why this happens – none are proven. What is known, is that re-built engines rarely display this startup smoke, so it’s definitely a sign of wear and tear – and it does progressively get worse with mileage. Vehicles that have sat for a while, such as winter storage for example, often blow more smoke at their first start rather than subsequent ones.

Extended smoking at startup is more of an issue. Again, there could be a number of reasons why this happens, but it is usually a sign of wear in the cylinders. See cylinder scoring below.

Sometimes, replacing the fuel injectors can help this problem. Worn and leaking fuel injectors cause fuel to sit in the intake path while the car is parked. The fuel leaking is not enough to cause starting problems, but it can be responsible for the smoke and wear in the cylinders – the excessive fuel heading into the cylinders washes oil off the cylinder walls causing wear on the piston rings and liners. The burning oil / fuel mixture makes more smoke.

The smoke at startup can also be caused by a bad air oil separator (AOS) that has not completely failed yet.

IMS Bearing – the Hype vs the Facts

Symptoms: Metal Shavings In Oil

M96 engines fitted to the 986 and 987 Boxster can have issues with a bearing at one end of the engine intermediate shaft. The shaft connects the two ends of the engine timing gear. At one end, the shaft drives the oil pump and at the other, finishes in a sealed bearing.

There’s no doubt that a cheap sealed bearing of the kind that sits at the end of the intermediate shaft on an M96, has no place in a performance engine. Porsche subsequently redesigned the engine to eliminate an IMS bearing after clearly identifying its potential for weakness.

However, the hype generated by people who have to gain from identifying the problem with this bearing and the real world results don’t quite match.

IMS Bearing Is a Weak Point

Yes, be clear, the IMS bearing is a weak point and it will fail. However, in the real world less than 5% have actually failed or can be directly linked to an engine failure. Porsche shipped approx. 77,000 vehicles to the USA that could have a bad IMS bearing. Even the most enthusiastic counting of IMS failures produces a total around 3500 or less than 5%. This means there are more than 73,000 vehicles out there that haven’t had the problem yet or have been retrofit with a newer bearing. Of course, that number excludes the cars driven into a ditch, wrapped around a lamp post, rolled off a cliff or set fire too, but you get the point. There are significantly more good M96 engines than bad ones.

Most competent shops will recommend replacing the bearing, at least as a safe guard against a future failure. Once the bearing has been retrofit, the value in the car is enhanced versus a vehicle that still has the original bearing.

Cylinder Bore Scoring – The Deadly Knocking Noise

Symptoms: Engine Knocking Noise, Oil Consumption, Black Exhaust Tail Pipe

The M96 and M97 engines found in the Boxster are famed for cylinder scoring – deep gauges in the cylinder liner, usually associated with a knocking noise and eventually catastrophic engine failure. The root cause of this issue is open to discussion, however, wear in the piston rings and liners causes the piston to wobble. The wobble occurs at the bottom of the stroke and results in the piston skirt dragging against the cylinder wall, thereby scoring the liner.

More recently, this issue has also been seen on the later engines. An early telltale sign can be excessive soot on the exhaust tailpipe on the Boxster. This is usually a sign of a difference in fuel mixtures and oil burning on one cylinder bank versus the other.

How to Detect Bore Scoring

The sound of this problem is not a tick like a bad lifter, it’s more a rhythmic knock and usually shows up first on the passenger bank of the flat 6 engines. Wear in the piston rings and the liners of the cylinder have caused the piston to wobble. The wobble occurs at the bottom of the stroke and causes the piston skirt to drag against the cylinder wall, causing scoring of the liner. The rhythmic knock is the piston changing position at the bottom of the stroke and hitting the liner. In many cases, even with the head off the engine, the worst scoring cannot be seen until the piston is removed – it can be way down at the bottom of the cylinder.

The only solution here is a replacement engine or rebuild and re-lining of the cylinders. A competent Porsche repair shop can help you through this process.

Timing Chain Rattle and Check Engine Light - 986

Symptom: Rattle Under Acceleration, Power Loss, CEL

This is a common issue on the older Boxster engines. A recurring check engine light under acceleration is the first sign. Subsequently, an engine rattle at startup or under acceleration becomes more prevalent and a CEL sets consistently.

Porsche Boxster Stretched Timing Chain

The typical cause of this problem is a stretching of the timing chains and failure of the timing chain tensioner. The only solution is to replace the tensioner and the timing chains. Porsche updated the timing chain tensioners to help eliminate this problem going forward.

This is an expensive job that requires engine removal and the right timing tools necessary to complete the work.

Find a local shop that can do the work for you.

Check Engine Light - Engine Runs Well

Symptoms: Check Engine Light, Engine Runs Well, No Loss of Power

There are many potential causes of a Check Engine Light on the Porsche Boxster and it’s important to read the engine codes or have a repair shop do that for you to assess the faults. Typically, an engine that sets faults yet runs well, suggests problems related to emissions control.

There are many potential causes of a Check Engine Light on the Porsche Boxster and it’s important to read the engine codes or have a repair shop do that for you to assess the faults. Typically, an engine that sets faults yet runs well, suggests problems related to emissions control.

Older M96 Engine Faults

One of the most common causes for a CEL on the older M96 engine in the Boxster is a failure in the O2 sensor and mass airflow systems (MAF). Commonly, the MAF begins to fail and delivers the engine management with inaccurate information regarding the flow of air into the intake.

This causes the engine management to adjust fuel mixtures using a set of parameters which were likely set too broadly by Porsche initially. The resultant adjustments cause the front O2 sensors to report faults and often lead to them failing completely. The fault codes will suggest faulty O2 sensors. This results in many folks just replacing the front O2 sensors in the hopes of solving the problem, only to discover that within a few hundred miles, the check engine light is back on.

Mass Air Flow Sensor Fault

The problem is actually caused by the MAF failing and by owners blindly believing the reported engine faults. The faults are an indication of the symptoms and not the route cause. The recommended solution is to replace both the MAF and front O2 sensors at the same time. Always use the original Porsche parts – the aftermarket versions do not work. Cleaning the MAF rarely fixes this problem.

Check Engine Light - Misfires - Engine Runs Rough

Symptoms : Engine Runs Rough or Lacks Power – Flashing CEL

Misfires can occur at any time on the Boxster engine and require diagnosis to identify which cylinders are misfiring and why. Common causes are worn spark plugs, cracks in ignition coils and oil leaking past the spark plug tube seals.

Misfires can occur at any time on the Boxster engine and require diagnosis to identify which cylinders are misfiring and why. Common causes are worn spark plugs, cracks in ignition coils and oil leaking past the spark plug tube seals.

The ignition coils on the M96 and M97 Boxster engines have been updated by Porsche multiple times. The original coils were prone to cracking and were replaced by a more substantial version. Low mileage older cars will commonly still have the older style coils and it’s best practice to replace them all to the newer version, even if only a single coil has failed.

Fuel Injector Malfunction

Fuel injector malfunction can cause a misfire, however injector failure of this nature is not so common on the Porsche flat 6 engines – even the older versions. More commonly, a failure in the wire or plug connected to the injector can cause a weak of misfiring cylinder. These wires and connectors can become brittle and crack, especially when being moved around for routine maintenance. Check the wiring thoroughly before replacing injectors.

High Pressure Fuel Pump Failure

On the later 718 Boxster with a direct injection engine, a failing high pressure fuel pump can also cause misfires and rough engine running. Typical signs are hesitation, lack of power and random misfires.

CEL and Misfire At Higher RPM

Symptoms : Engine Runs Well Up To 4K RPM then Misfires

This is a problem that many so-called experts will tell you doesn’t exist. However, we have diagnosed and fixed this issue on a number of Boxster engines.

If you have the issues, you find the engine runs perfectly below 3K rpm. Revving the engine above 4K rpm causes a misfire to be reported on a single cylinder and engine management shuts off the cylinder. Consequently, below 3K rpm the engine now runs rough until the fault is cleared. Once the fault is cleared the engine runs perfectly again below 4K until the fault is triggered again.

Typically, this happens to a single cylinder repeatedly. Initially, this sounds like a failing spark plug, injector or coil and can indeed be solved by replacing them, if you’re lucky. However, if you have replaced both the coil and the plug and still have the same problem, there is another solution.

Intake Valve Lifter Problem on Porsche Engines

The Porsche flat 6 engine (in particular the M96) has a two-stage intake lifter that fails. As you accelerate the engine rpm, the lifter expands to increase valve lift. The lifter commonly breaks and during the second stage of valve lift, which occurs above 4k rpm, it does not function correctly – this results in a misfire on a single cylinder. The engine management then shuts off the cylinder until the fault is cleared.

The Porsche flat 6 engine (in particular the M96) has a two-stage intake lifter that fails. As you accelerate the engine rpm, the lifter expands to increase valve lift. The lifter commonly breaks and during the second stage of valve lift, which occurs above 4k rpm, it does not function correctly – this results in a misfire on a single cylinder. The engine management then shuts off the cylinder until the fault is cleared.

This problem can be solved by replacing the lifters on the particular cylinder on which the fault occurs – although replacing all the lifters on that particular bank, whilst expensive, is probably the recommended solution. If left alone, the lifter can stick causing a permanent misfire or worse.

In a couple of customer cases that we’ve seen, the stuck lifter went on to break the intake camshaft destroying the bearings in the valve cover. We also experienced a Boxster engine where the lifter had been ejected out of the valve cover, leaving a nicely sized hole and very oily mess. In both these cases the engines were repaired and functioned perfectly afterwards.

Replacing lifters requires specialized skills and timing knowledge – we recommend you seek the help of an independent repair shop.

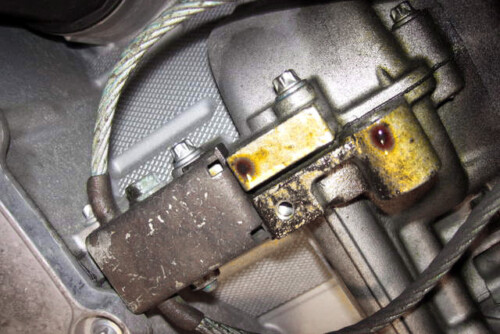

Cam Solenoid Failure - Check Engine Light

Symptoms : Check Engine Light and Lack of Power

The M96 and M97 engines found in the Boxster have variable valve lift and timing. Part of the variance is controlled by the cam solenoids located in the valve covers. The cam solenoid is an electro-mechnical device that redirects oil pressure as per the demands of engine management. The increase in oil pressure enables valve lift adjustment.

Cam Solenoid Failure Porsche Engine

Problems with these solenoids are often the cause of a CEL and a lack of power under acceleration. Scanning the engine management system should provide fault codes which identify the solenoids that are failing. Replacing them usually solves the problem.

Some of the cam solenoids can be replaced without the removal of the valve cover; however, others do require the valve cover removal and are more intense work especially on the Boxster. We recommend inspection of the wiring to the solenoids before replacing them – these can become corroded on older cars due to their location.

Stuck Spark Plugs – Low Mileage Cars

Symptoms: Broken Spark Plug, Misfires, CEL

Symptoms: Broken Spark Plug, Misfires, CEL

This is a problem that is simple to prevent but often overlooked. Older, low mileage cars regularly still have their original spark plugs. Normal servicing requires the plugs to be changed at 30K mile intervals. However, with many Boxsters being used as low mileage weekend cars, the service intervals for the spark plugs are not reached.

Plugs that have been in the engine for more than 10 years can be very difficult, if not impossible, to remove. A stuck or broken plug in the head is an expensive problem to solve and one that can be simply avoided. Check the last time your Boxster had a spark plug change – no harm is done by changing the plugs more often than the recommended 30K interval.

Engine stumbles, misfires, loss of power, poor acceleration, CEL - 718

Later Porsche Boxster engines feature direct injection and a high pressure fuel pump driven from a camshaft. The high pressure fuel pump is subject to failure and typically, initially sets a check engine light and faults associated with the fuel rail pressure.

Later Porsche Boxster engines feature direct injection and a high pressure fuel pump driven from a camshaft. The high pressure fuel pump is subject to failure and typically, initially sets a check engine light and faults associated with the fuel rail pressure.

Typical symptoms of a failing high pressure fuel pump include:

- Delayed start of the engine or long crank time

- Hesitation or sputtering in acceleration

- Lack of power

- Higher engine temperatures

- Engine stalling and being difficult to restart

Oil Level Too High or Too Low - Topping Off Oil Level - 718

Symptoms: Warning Message Oil Level Too Low or High

If you experience an oil level too high or too low message, be careful. First, there is no dipstick – brilliant idea most of the German car manufacturers have implemented. The oil level is measured electronically for accuracy. This is awesome, assuming the electronic measurement is accurate or is at the very least telling you the truth. There is no manual backup of the tried and trusted dipstick – so did you overfill or under fill? Or do you have a faulty sensor?

If you experience an oil level too high or too low message, be careful. First, there is no dipstick – brilliant idea most of the German car manufacturers have implemented. The oil level is measured electronically for accuracy. This is awesome, assuming the electronic measurement is accurate or is at the very least telling you the truth. There is no manual backup of the tried and trusted dipstick – so did you overfill or under fill? Or do you have a faulty sensor?

Is The Oil Level Sensor Telling The Truth?

You have to be sure of which one before you take action. The only way to be sure is confirm the amount of oil in the engine by draining and measuring. We’ve experienced an oil reading that went down when we added a quart!

Don’t be surprised if the oil level sensor is not telling the truth but, make sure you are certain that the oil level is correct before ignoring the sensor and replacing it.

Oil Level Top Off

The Porsche turbo engines will naturally consume oil while you drive. Different driving styles and conditions will cause oil consumption to change. With the extended mileage between oil changes that manufacturers have opted for, it’s very likely the car will call for additional oil between scheduled service intervals. Most independent shops consider the extended mileage range between oil changes too extreme and simply a marketing gimmick.

The Porsche turbo engines will naturally consume oil while you drive. Different driving styles and conditions will cause oil consumption to change. With the extended mileage between oil changes that manufacturers have opted for, it’s very likely the car will call for additional oil between scheduled service intervals. Most independent shops consider the extended mileage range between oil changes too extreme and simply a marketing gimmick.

If your Boxster calls for additional oil, here’s what to do:

- Ideally, the engine should be at operating temperature

- The difference between the min and max reading is approx. 1 quart

- Do not add more than 1 quart at a time

- Remeasure the oil level after each quart added

- After adding a quart, drive the car for 5 mins before rechecking

- Oil reading is not instant and requires a drive cycle

Diagnostic Computer Required For Oil Fill

The latest cars require the use of the PIWIS to correctly fill the oil level. This is an extended process that requires connecting the PIWIS and perform an oil measurement procedure with the engine running. The system will then conduct an oil measurement when the recommended engine temperature is reached. The PIWIS will then recommend the amount of oil needed to complete the refill.

Unfortunately, this process can take quite a while and may need to be repeated several times to accurately set the correct oil level.

Exhaust

Exhaust Rattle and CEL for Catalytic Converter Efficiency

Many Boxster models are starting to experience failure of their catalytic converters and mufflers. In many cases, the main exhaust header pipe leading to the cat converter will crack and fail completely.

Many Boxster models are starting to experience failure of their catalytic converters and mufflers. In many cases, the main exhaust header pipe leading to the cat converter will crack and fail completely.

Exhaust Rattle and Muffler Failure

Initially, you’ll start to notice a rattle back there. This is caused by the muffler, the cat or both coming apart internally. While annoying, it’s also potentially destructive – a partial blockage in the exhaust can cause the engine to not run or worse, it will cause immense heat to build at the blockage point. Seeing a catalytic converter glowing bright orange under the bumper of a Boxster is quite disconcerting! This has car fire written all over it!

The disintegration of the catalytic converter typically causes a check engine light with emission fault codes associated to converter inefficiency. This means you can’t pass the emissions test and in some states that means not driving the car at all.

Cooling System

Oil and Coolant Mixed - Peanut Butter!

Symptoms : Oil Residue in Coolant Reservoir – Peanut Butter!

Symptoms : Oil Residue in Coolant Reservoir – Peanut Butter!

Under the worst circumstances, oil in the coolant can look like peanut butter in the coolant reservoir. It typically starts out as an oily film and continues to get worse over time. There are many potential problems associated with this sign – oil could be getting in to the coolant from a blown head gasket, or from a crack in the cylinder head, or a crack in a cylinder liner, or the oil cooler. For sure, coolant in the oil and visa versa is a bad sign and diagnosing the problem often requires multiple steps.

Boxster – Oil in The Coolant – The Easy Approach

The simplest place to start is by replacing the oil cooler – this is the easiest and least expensive item to tick off the list of possible problems. Generally the likely issue is caused by the coolant and oil swapping places through the oil cooler membrane.

Assuming the the oil cooler is the issue, it sits beneath the intake and is exchanging heat between oil and coolant at a barrier level. When the barrier separating the two fluids inside the cooler breaks down, fluid can be exchanged – sometimes in both directions. The result is oil in the coolant and worse, coolant in the oil. Coolant in the oil is a quick way to needing a new engine!

Replacing The Oil Cooler

Replacing The Oil Cooler

If after replacing the cooler, you need to go to the next stage, having a new oil cooler is not the end of the world and at least eliminates the cooler as the source immediately.

If replacing the cooler does not solve the problem, the remaining options are expensive and likely require major engine surgery. This is where a specialized repair shop can help to quickly and cost effectively get to the route cause of the issue.

Coolant Leaks - Radiators, Hoses and Water Pumps

Symptoms : Low or Flashing Coolant Light

In general, the Porsche Boxster has a pretty reliable cooling system. There are however, a number of weaker areas that can sometimes cause issues.

Coolant Reservoir Leaks

One of the most frustrating leaks is a small crack in the coolant reservoir. This happens on all models and usually shows up as a coolant smell while driving with minor loss of coolant over a period of time. Eventually a minor crack will split wide open and empty the reservoir rapidly – this is to be avoided if at all possible. Replacing the reservoirs on Boxster is not expensive but can be a pain.

You should never loose coolant while driving, although the later turbo engines on the 718 do consume some coolant. If your coolant level does decline over time more than the recommended amount, find the cause and solve it asap. Under worst circumstances this could be a sign of a cracked cylinder liner on the older M96 or M97 engines.

Loss of coolant can quickly cause overheating of the engine and catastrophic failure.

Leaking Radiators

On the Boxster, the radiators are low down and exposed to incoming road debris. Small holes in the radiator can be difficult to see without removing the front bumper and searching for the telltale white coolant stain. Often the holes are not caused by debris hitting the radiator but are due to deterioration of the seals in the corners of the radiators.

On the Boxster, the radiators are low down and exposed to incoming road debris. Small holes in the radiator can be difficult to see without removing the front bumper and searching for the telltale white coolant stain. Often the holes are not caused by debris hitting the radiator but are due to deterioration of the seals in the corners of the radiators.

Leaf and road debris is not easily cleaned out from the depths below the bumper and can hold moisture against the radiator causing metal corrosion. We recommend cleaning the radiator areas regularly or adding aftermarket screens to the front of the openings to reduce the problem.

Leaking Hose Connectors

The newer models have the push-click-lock type of hose connector – no clamps. These are easy to get on and off but have a nasty habit of becoming one-time use if not removed carefully. If you have to remove a hose with this type of connector, ensure that when replaced it does not leak under extreme pressure. Of course, if it does, you need to replace the complete hose and not just the connector.

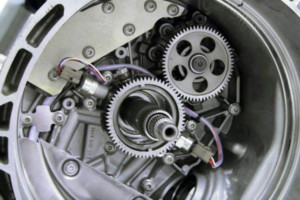

718 Water Pump Failure

Water pumps fail regularly. This is not news, but some solutions have been over hyped.

Water pumps fail regularly. This is not news, but some solutions have been over hyped.

The bearing in the water pump supporting the shaft wears and the shaft starts to wobble. This develops into a knocking noise sometimes accompanied by a coolant leak. The plastic impeller can degrade rapidly and spread flow-blocking plastic throughout the cooling system. Getting plastic debris out of the front radiators is difficult and time consuming.

The water pump is simple to reach through the interior access panel and checking the amount of play on the pulley is relatively simple. With the engine running, observe the pulley and see if there is any sign of wobble.

The hype – get rid of the original plastic impeller pump and replace with a metal impeller water pump. This seems like a solid idea, right up to the point where the bearing fails again. Now the metal impeller will wobble and score the inside of the cylinder block causing permanent damage. In some cases, the damage is so severe that the engine case half would need to be replaced. Additionally, metal flakes are now floating around the coolant system.

We recommend sticking with the plastic impeller and inspecting the pump on a regular basis. It’s easy to see when the engine is running and you just have to watch for the wobble. If in doubt, the work to replace it is quite simple and should be considered a 40K or 4 year item of preventative maintenance.

Front Coolant Pipe Leak

The 2.7L and 3.4L Boxster engine features a plastic coolant pipe that connects the front of the engine to the primary cooling outlet hose. The rubber seals between the plastic part and the engine block degrade to produce a minor coolant leak down the front side of the engine. This part has been updated a number of times by Porsche.

The 2.7L and 3.4L Boxster engine features a plastic coolant pipe that connects the front of the engine to the primary cooling outlet hose. The rubber seals between the plastic part and the engine block degrade to produce a minor coolant leak down the front side of the engine. This part has been updated a number of times by Porsche.

Random Over-heating – Cracked Cylinder Liner 986 987

Symptoms: Engine Overheats and Loss of Coolant

Each cylinder bore in the engine case half of the Boxster engine is lined with a one-piece sleeve or liner. A crack in the cylinder liner of the engine can show up in a number of ways from overheating, loss of compression to oil consumption. Often, the problem is not simple to diagnose because the cracks can take a long engine running period before they start to work their magic.

987 Boxster Cracked Cylinder Liner

Here’s a first hand example. Customer tows a 987 to us. A coolant hose had exploded – one of the main pipes leading to the front radiators. Customers says the car didn’t over-heat, the hose just exploded. We replaced the hose, refilled the coolant, test drove the car for 30 mins – everything was perfect.

The customer calls the day after picking up the car and driving 1-hour to get home – the car flashes low coolant light and we establish that all the coolant has disappeared from the reservoir.

We scanned the car – no overheating and no faults or events were recorded. We know we filled the coolant to the correct level initially so, we refilled the coolant, ran the engine and drove the car – it’s perfect. Where did that coolant go?

Suspicious of a cracked liner, we decided to let the engine run at idle for a while. The engine ran perfectly at a steady temperature for approx. 55 mins. Then all of a sudden, it rapidly started to get hot, a coolant burning smell appeared in the exhaust and the coolant level started to drop quickly. Once the engine had cooled down, we could repeat this perfectly – approx. 55 mins of running and it would overheat and consume the coolant.

Long story shortened – once we had dissembled the engine, we found a series of micro fractures in the cylinder linings. It took nearly an hour of running for these cracks to open enough for the engine to start consuming the coolant. The engine required a full rebuild and liner replacement to solve the problem.

AC System Will Not Blow Cool Air

Symptoms: Warm Air From Air Conditioning System or Loss of Refrigerant Over Time

Symptoms: Warm Air From Air Conditioning System or Loss of Refrigerant Over Time

If your Boxster AC system blows warm air, the most common issue is a lack of refrigerant. Over time the refrigerant from the AC system will find its way out of the hoses and joints. If, however, you refill the system and sometime later the system is again low on refrigerant, there is clearly a larger than normal leak.

Damaged Front Condensers

Leaks can occur at any section joint or hose, however, one of the most common and missed places for the leak is at the lower corner of the front condensers.

Debris from leaves and road dirt can build up tucked in the extreme lower corner of the condensers of the Boxster. The debris can hold moisture and degrade the aluminum to point were a hole can appear. This is almost impossible to see or clean out without the bumper being removed.

The refrigerant leak often goes undetected, even to a sniffer, without the debris being cleaned away. Check this thoroughly before making any other assumptions. The AC compressor for example, rarely has issues and a low refrigerant situation can prevent the compressor from engaging.

Air Direction Flap Failure or Heater Shut Off

Faulty Change Over Valve (COV) Solenoids

Faulty Change Over Valve (COV) Solenoids

The vacuum solenoid or change over valve has been an issue on all the 981 chassis.

The device is designed to direct engine vacuum to effect a mechanical change when requested to by an electrical control unit e.g. open a vent, change the position of an exhaust flap, redirect hot air from feet to screen etc. Likely systems effected include:

1. Air Cleaner Flap

2. Acoustic Simulator

3. Heater Shut-Off Valve

4. Exhaust Flaps

5. Coolant Shut-Off Valve on Engine Bypass Circuit

6. Tuning Flaps

7. Shut-Off Valve on Heat Exchanger for Gear Wheel Set Oil

8. Shut-Off Valve for Clutch Fluid Heat Exchanger (PDK ONLY)

9. Fuel Tank Vent Valve

Porsche has used the COV in many circumstances throughout the 981 chassis, so if you have a failure related to a mechanical device controlled by vacuum, look for a failure in the COV solenoid in the system first.

Front Coolant Fan Runs Continually

A common failure on the 718 cars is a left or right side radiator fan running continually at high speed at start up or during short drives even in cold outside temps. This is typically caused by a failed relay.

A common failure on the 718 cars is a left or right side radiator fan running continually at high speed at start up or during short drives even in cold outside temps. This is typically caused by a failed relay.

The cooling fan system is designed to run permanently with the relay activating the stop when the coolant temp does not require the fan to run. With a failed relay the default is for the fan to run continuously for protection against over heating.

Transmission

Gear Shift Cable Problems - Sloppy Gear Change - Manual Transmission

Symptoms: Gear Shifter is Floppy or Loose, Inconsistent Gear Changes or Stuck In Gear

Symptoms: Gear Shifter is Floppy or Loose, Inconsistent Gear Changes or Stuck In Gear

Boxster models fitted with a manual transmission can often experience problems with the gear shifter mechanism.

The gear shifter operated by the driver, is connected to the transmission by two cables. Over time these two cables become worn and the result is a sloppy gear change, missed gear or a transmission that refuses to come out of the gear selected.

Checking the Shift Cables For Wear

There’s lots of potential for these two cables to have issues at either end. At the transmission end the cables can break, the small connectors on the end of the cable come off and they can degrade with exposure to the elements. At the shifter end, the cables can become notchy, worn or stretch.

Upgraded Cables and Short Shifter

There is adjustment in the cables, however the original cables in the older cars have been improved and we recommend replacing them. Missing a gear through a worn shifter cable is a recipe for disaster and can lead to serious engine or transmission damage.

There is adjustment in the cables, however the original cables in the older cars have been improved and we recommend replacing them. Missing a gear through a worn shifter cable is a recipe for disaster and can lead to serious engine or transmission damage.

Upgraded versions of the cables typically produce a crisper and better feeling gear change. The movement or throw on the Boxster shifter has always been a little long. While cable replacement work is underway, it’s a great time to install a short throw shifter to replace the factory version.

PDK Issues - Transmission Failure

Symptoms: PDK Failure Light, Rough Gear Changes, Transmission Faults, Emergency Transmission Run Warning on Dash

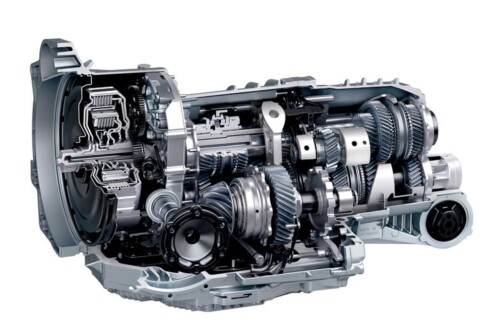

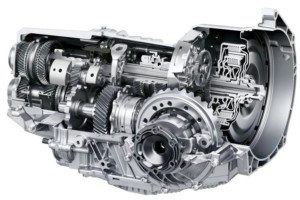

The Porsche-Doppelkupplungsgetriebe – which translates to Porsche double-clutch transmission or PDK (now that’s when you really need an acronym!) has been the subject of a number of failures. Porsche Boxster owners have experienced failure of the PDK transmission. For more information, see our page dedicated to PDK failures, symptoms, and faults with potential resolutions.

The PDK is an automated manual transmission. Two units matched together – a manual transmission rear section and automated dual clutch front section. The manual transmission rear section is very solid and reliable. Most issues occur with the electronic and hydraulically controlled clutch section at the front of the transmission. Physically, the PDK is a ZF transmission unit that has been around for a number of years. VAG took multiple versions of the transmission and personalized them for their various car ranges. Porsche adapted the software and labeled their version PDK.

There are a number of ways in which the PDK in the Boxster can fail. Most show up as a collection of warning lights on the dash and an eventual refusal to do anything. The only viable solution for most people is the replace the PDK – this is very expensive. However, much of the need for replacement of the PDK comes from a lack of understanding, unavailable parts and an unwillingness to dig deep.

Components and Failures

Transmission Control Module – TCM

The connection to the car and communication of instructions to the transmission, come from an external module called a transmission Control Module (TCM). While this rarely has issues, it can become confused and has been the subject of a number of software revisions. Re-flashing the TCM doesn’t usually solve problems, but ensuring you have the latest software revision can’t hurt. This is where diagnostic faults are stored.

The connection to the car and communication of instructions to the transmission, come from an external module called a transmission Control Module (TCM). While this rarely has issues, it can become confused and has been the subject of a number of software revisions. Re-flashing the TCM doesn’t usually solve problems, but ensuring you have the latest software revision can’t hurt. This is where diagnostic faults are stored.

Mechatronic Unit – Valve Body

The TCM sends instruction to the Mechatronic unit or valve body inside the transmission. The Mechatronic unit is a complex series of electronics, hydraulic valves and sensors. These devices are managed by a control module attached to the Mechatronic unit. This is the system which enables gear changes and controls the transmission functionality.

Problems with the Mechatronic unit vary, but commonly include failure to select gears, rough gears changes, etc. The physical components of the transmission are robust, so this unit is often the most economical place to start for most issues.

Internal Sensors

Connected to the Mechatronic unit are a number of sensors throughout the transmission. These determine the operating conditions within the transmission. For example, the temperature of the fluid, the rotational output speed, hydraulic clutch pressure and movement of gears selectors. Failure of these sensors is very common. Early on, Porsche routinely replaced the wiring and trans temp sensor in most of the PDKs.

Connected to the Mechatronic unit are a number of sensors throughout the transmission. These determine the operating conditions within the transmission. For example, the temperature of the fluid, the rotational output speed, hydraulic clutch pressure and movement of gears selectors. Failure of these sensors is very common. Early on, Porsche routinely replaced the wiring and trans temp sensor in most of the PDKs.

However, the problem did not go away and has re-occurred on the same transmissions further down the road. The temp sensor problem can show up on almost any model with a PDK. See our PDK problems page for more detail on the sensor problems.

Clutch Pack

The clutch pack has proven to be very robust and generally does not fail with normal use. Over extended mileage this will become a wear component that will need to be replaced. The failures of the clutch that have occurred, are usually on performance enhanced engines delivering too much torque for the clutch plates. At higher torques, the clutches slip resulting in highly accelerated wear and early failure.

The clutch pack has proven to be very robust and generally does not fail with normal use. Over extended mileage this will become a wear component that will need to be replaced. The failures of the clutch that have occurred, are usually on performance enhanced engines delivering too much torque for the clutch plates. At higher torques, the clutches slip resulting in highly accelerated wear and early failure.

The PDK transmissions in the later cars are very complex and the technology involved is a closely guarded secret. Technicians at Porsche are not required to dissect the transmission and make repairs. They will replace the Mechatronic unit, but often they just replace the transmission as a whole.

Don’t Replace Your Porsche PDK Transmission – It Can Easily and Economically Be Repaired

Don’t Replace Your Porsche PDK Transmission – It Can Easily and Economically Be Repaired

Expert Porsche PDK Transmission Repair Service

The good news is the Porsche PDK transmission is fully repairable for a fraction of the cost of replacement. And in more good news, repairs of the PDK transmission have led to expert knowledge to be able to recommend additional preventative maintenance that can help avoid the common issues that arise with the PDK.

Recommended Porsche PDK Repair Specialist

We have partnered with MC Squared Autosport and highly recommend their Porsche PDK transmission repair service.

Clutch Pedal Stuck Down

Symptom: Clutch Pedal Stuck Down and Leaking Fluid

Symptom: Clutch Pedal Stuck Down and Leaking Fluid

The early Boxster featured a plastic clutch slave cylinder that was subsequently update to a metal version after initial failures. The original clutch slave cylinder can easily fail leaving a fluid mess and a stuck pedal.

Bleeding the Clutch Slave Maintenance

The clutch slave cylinder should be flushed in the same way that a brake fluid flush is performed on the Boxster. The flush of the slave cylinder should be completed at the same time as a brake fluid flush. Build up of debris and old fluid in the clutch slave cylinder causes inefficient operation of the clutch and can lead to difficult gear changes and wear of the clutch plate.

Brakes - PSM

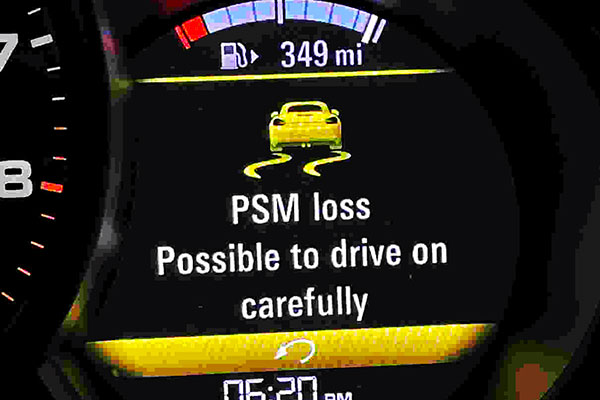

PSM Failure

Here’s What to do When You See PSM Failure on Your Porsche Dashboard

Here’s What to do When You See PSM Failure on Your Porsche Dashboard

PSM failure can be a common issue on the Boxster, however, because the system is so interconnected, the message PSM failure can be deceptive. The PSM per se has not itself failed. The likelihood is a single sensor or component connected to the system is broken. The interconnection of the systems can result in the reporting of multiple faults and cause significant confusion to the untrained. Commonly a single sensor failure will report multiple faults in various systems. Proper diagnosis of the root cause will save you money versus part replacement guess work.

If you see PSM messages that also include ABS see our page on brake system messages.

ABS Warning Light

This warning light is associated with a failure in the ABS system on older cars and is shown as a message in the later cars. A minor fault in the system can cause this light to be illuminated.

This warning light is associated with a failure in the ABS system on older cars and is shown as a message in the later cars. A minor fault in the system can cause this light to be illuminated.

In many cases this can be as simple as a wheel speed sensor.

Power Brake Error Service Required

This message indicates a problem with the vacuum assist on the brake booster. It is most commonly seen on start up.

This message indicates a problem with the vacuum assist on the brake booster. It is most commonly seen on start up.

Here’s what to do – in some cases this error has been resolved through a software update and modification to the vacuum supply line to the brake booster. It is often erroneous but should not be ignored.

Have the fault investigated through a diagnostic scan of the system with Porsche specialist as soon as possible.

Fault Electric Parking Brake

This message relates to the ability for the electrical system to operate the parking brake. The parking brake is applied via electric motors.

This message relates to the ability for the electrical system to operate the parking brake. The parking brake is applied via electric motors.

Here’s what to do – Hopefully at this stage the parking brake is off. Do not attempt to operate it. If the parking brake is stuck on, then a painfully expensive tow charge will likely apply!

Suspension and Steering

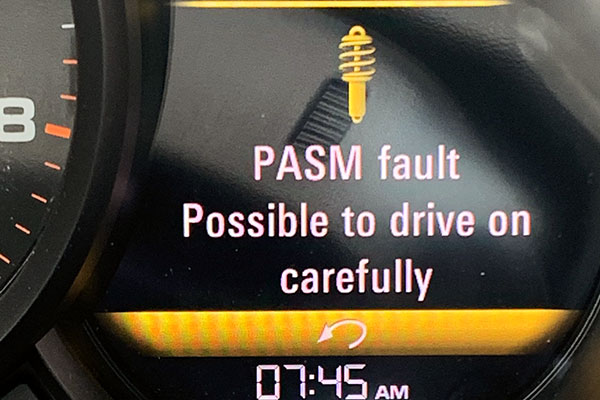

PASM Failure

The PASM or Chassis warning messages on the 718 Boxster are never very specific. Problems in the system vary dramatically from a simple ride height sensor, through a leaking strut, to suspension pump problems. Confusingly, the system will always attempt to level the car at least across one axle if possible. This often disguises the actual problem and sets multiple faults.

The PASM or Chassis warning messages on the 718 Boxster are never very specific. Problems in the system vary dramatically from a simple ride height sensor, through a leaking strut, to suspension pump problems. Confusingly, the system will always attempt to level the car at least across one axle if possible. This often disguises the actual problem and sets multiple faults.

Because the system is so much more than just ride height adjustment, we highly recommend you seek the professional guidance of a Porsche specialist to diagnose and make repairs to solve the PASM failure message.

Electronic Power Steering Fault

Later Boxster models feature electronically assisted power steering. Fault messages associated with the power steering typically indicate a loss of steering assistance or support and suggest you can drive on. This means the steering will feel heavy and requires more effort. This can be a potentially dangerous situation and should be diagnosed as quickly as possible.

Later Boxster models feature electronically assisted power steering. Fault messages associated with the power steering typically indicate a loss of steering assistance or support and suggest you can drive on. This means the steering will feel heavy and requires more effort. This can be a potentially dangerous situation and should be diagnosed as quickly as possible.

Failure of the electronic steering rack is not that common. These faults are normally caused by power supply failure through a faulty relay.

Knocking noise from front or rear suspension

Often a knocking or low thud can be heard from the front suspension on an older Boxster and commonly on the rear of the 981. This is often caused by the drying or failure of the upper shock or strut mount. Above the front and rear suspension strut is a plate with a rubber bushing. The rubber commonly drys and declines over time. This allows the strut to move and hit the body as it rides over bumps producing a low frequency thump.

Often a knocking or low thud can be heard from the front suspension on an older Boxster and commonly on the rear of the 981. This is often caused by the drying or failure of the upper shock or strut mount. Above the front and rear suspension strut is a plate with a rubber bushing. The rubber commonly drys and declines over time. This allows the strut to move and hit the body as it rides over bumps producing a low frequency thump.

PADM Fault

Porsche PADM is active drivetrain mounts. Essentially, these are electronically controlled engine mounts designed to stiffen side to side and when launching the car. These electronically controlled engine mounts also control the engine movement when cornering and are designed to improve performance, comfort, and stability.

Porsche PADM is active drivetrain mounts. Essentially, these are electronically controlled engine mounts designed to stiffen side to side and when launching the car. These electronically controlled engine mounts also control the engine movement when cornering and are designed to improve performance, comfort, and stability.

The engine mounts commonly fail and many have been replaced before an updated version was available. Worth checking the wiring and the connector before assuming the engine mount has failed.

Electrical System

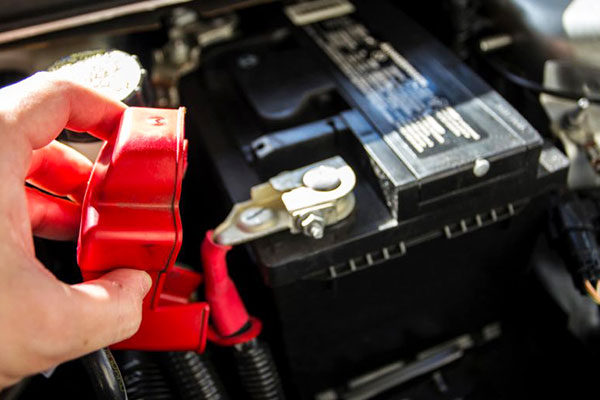

Low or No Battery Power

Symptoms : No Crank or Slow Crank

Symptoms : No Crank or Slow Crank

Porsche Boxsters are often garage queens and not driven as much as many other cars – rarely are they daily drivers. During any down period the car will continue to use some battery power – in Porsche’s case, usually more than would be expected from similar vehicles. This can very quickly lead to a flat battery.

Losing battery power resets a number of important systems and can cause unnecessary headaches with everything from emissions to electronics and comfort items such as cabrio roofs. We recommend you use a battery maintainer any time you store or do not drive the car for an extended period – 2 weeks or more. Leaving the battery to drain completely usually shortens the life of the battery as well.

How To Access The Battery With No Power

A flat battery on a Boxster can be a pain. To access the battery or engine compartment requires battery power for the electric hood release – not easy with a flat battery. If this happens, use the following procedure:

- Open the left door

- Connect an external battery power source to fuse C3 in the interior fuse panel

- With the door open, flip the door latch mechanism to the closed position

- Use the key to lock and unlock the door

- The front hood release should now function

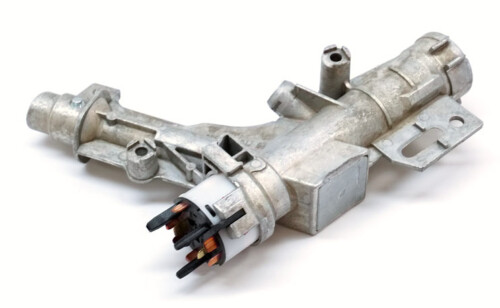

Ignition Switch Failure - Stuck Key - Key Problems

Symptoms: Key Stuck in Ignition or No Start

Symptoms: Key Stuck in Ignition or No Start

This is a common failure on the Boxster. Turning the key will not start the car or the key has become stuck in the ignition switch.

This problem is typically caused by a failure in the ignition switch mechanism. Replacing the electrical portion of the switch is fairly straight forward and typically solves the no start problem immediately.

However, on some occasions it may be necessary to replace the mechanical portion of the switch as well. This is a little more involved and requires some additional skills. We’d recommend a repair shop tackle this problem for you.

Key Failure

The ignition key communicates with the car during the starting procedure. The key includes a small electronic transmitting device that is matched to the car and a small battery to power it. If the key fails to open or lock the doors and will not start the car, replace the battery in the key first, paying particular attention to the orientation of the original battery.

The ignition key communicates with the car during the starting procedure. The key includes a small electronic transmitting device that is matched to the car and a small battery to power it. If the key fails to open or lock the doors and will not start the car, replace the battery in the key first, paying particular attention to the orientation of the original battery.

On some occasion it may be necessary to replace the internal electronics of the key or the whole key itself. This can be done by some third party repair shops with the right access to Porsche systems, however, because this is a security device it may be necessary to visit your local dealer.

No Window Drop With Door Opening

Symptoms: Windows Do Not Drop On Door or Top Opening

Symptoms: Windows Do Not Drop On Door or Top Opening

If your Porsche Boxster battery has gone flat or required a change, you may experience this issue. This issue, if related to battery power, can be generally solved through performing a vehicle handover using the diagnostic device.

However, if the condition is not related to battery failure, then it is likely there are a number of other scenarios that can cause the window to misbehave:

- Window does not drop when opening the door from the inside: This is usually caused by the inner door handle micro switch malfunctioning.

- Window does not drop when opening the door from the outside: This is usually caused by the outer door handle micro switch malfunctioning.

- With the door open, the window goes back up when you release the door handle, making it very difficult to close the door with the glass all the way up. Alternatively, the window does not drop when using either the inside or outside door handle: This is usually caused by the door latch mechanism micro switch.

- When operating the convertible top, neither windows drop: This is usually caused by the convertible top latch micro switch.

- If a window does not drop enough and you can push down the window the extra travel before stopping, the typical cause is the window regulator.

Go through the functionality of the door and window in question from locking to unlocking to open close from both inside and out. Commonly, this will narrow down the problem to a micro switch in one of the above mentioned areas.

Interior Electrical Misbehavior - Random Faults

Symptoms: Random Interior Faults – Windows, Seats, Air Bag etc.

Symptoms: Random Interior Faults – Windows, Seats, Air Bag etc.

This problem is most prevalent in Boxster models because of the cabrio roof.

On occasion, the Boxster will exhibit strange and seemingly random electrical misbehavior of interior systems. This could be interior lights staying on, air bag faults, seat malfunctions, etc. Often this can be traced back to a single control module. Porsche placed the module that controls interior settings under the drivers seat.

Due to the location and proximity to the driver door and window, this module can sometimes become water damaged – especially on cabriolet models like the Boxster. Once the module has got wet, it will often take time to slowly corrode and produce strange electrical faults or misbehavior.

If you left the top down in a rain shower, had the driver window open when it was raining, your top leaks, or live in a climate where significant rain could enter when the driver door is open, you’re a good candidate to have this problem.

Bodywork and Cabriolet Top

Cabriolet Top Malfunction

Symptoms: Top Wont Move or is Lopsided Going Up or Down

Symptoms: Top Wont Move or is Lopsided Going Up or Down

All of the Boxster cabriolet tops experience issues at one time or another. These vary from the degrading of the rear window to the unbalanced or lopsided opening and closing.

The window is easy – a good automotive upholstery or top center can replace that old, tired plastic rear window very economically. In fact, some good shops will offer a glass window replacement upgrade.

The other issues with the top that concern opening and closing, usually have a simple cause – first, the older Boxster received a revised set of motors and drives to cure the most common problems. On a low mileage car this typically means you’ll have to replace the entire drive system, as the newer versions are not compatible with the older components.

Secondly, the bushings on some of the support arms fail over time and this causes the common lopsided effect during a closing or opening procedure. This is a relatively inexpensive fix by replacing the support arm.

Diagnosing Cabriolet Top Malfunction

While the opening and closing of the top involves a number of components and can seem complex, in reality, the top movement is quite simple. There are a series of steps from the press of the button through to the completion of the procedure. If a step is not completed or will not operate, the top will not open or close correctly. Simply follow each step and make sure the step is functioning correctly.

A note on storage – don’t store the car with the top down. The top tends to shrink and after a few years will not stretch enough to reach the closed position. Always store the car with the top up.

Hood or Engine Lid Will Not Stay Open

Symptoms: Lift The Lid and It Falls Down On Your Head!

Symptoms: Lift The Lid and It Falls Down On Your Head!

This is very common and very annoying for the person with their head stuck in the trunk looking for something.

The hydraulic struts on either side of the hood or lid fail over time. This is annoying but also dangerous – the latch on the hood can give your head a nasty blow if it falls down unannounced.

Replacing the struts is simple and they are available online at low cost. You’ll have a much better relationship with a repair shop that works on your car if you fix these, not to mention the cost of the lid falling on the wife!

General Issues

Winter Storage Problems - Rodents!

Symptoms: Unusual Electrical Behavior

Symptoms: Unusual Electrical Behavior

In some regions, such as the Midwest or Northeast, cars are often stored over the winter months and not driven much until all that nasty white snow stuff disappears. However, the fact that you have your car tucked away in a warm, clean and perfect garage does not mean that its is alone!

Our small rodent friends that we share this planet with, are seeking out the exact environment you have created for your Boxster storage. Small rodents are experts at finding a safe place and hiding beyond your view.

What Looks Good To A Rodent?

The cabin air filter makes the perfect place for a warm nest – when was the last time you looked in there? Also, the center of the engine, right below the intake, is a perfect place for the safe consumption of food. It’s supplemented by wires that are coated with a plastic made from corn and on cold, long dark winter nights when food is in short supply, that wire seems pretty tasty. Of course, you are blissfully unaware of all of this until the car displays strange engine faults and a musky odor from the air vents!

On one occasion, we removed a whole mouse family from a Boxster that had eaten the wiring harness, destroyed the carpets, (top stored down) and had eaten most of the cabriolet top.

Take rodent precautions even if you are certain you don’t have that problem.

Still Can’t Find An Answer? – Contact Us For More Help

If your Boxster has mechanical issues that don’t appear here, simply drop us an email via the forms or pop-up contact and we’ll do our best to share a solution with you.